Positive Displacement

Positive Displacement

Since 1982 Summit Pump, Inc has manufactured quality pumps and pump parts for industry worldwide. The company mission statement is more than just a plaque on the wall; it is how we strategically go to market. We will “provide quality pumping products in a timely manner, at a fair market price”. Located in Green Bay, Wisconsin we are a privately held and financially strong company. We sell our products worldwide via a dedicated and exclusive distribution network. We pride ourselves in being the Best Value in the market.

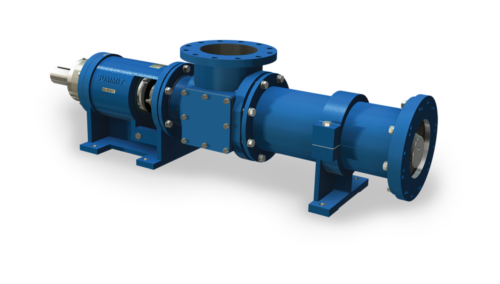

SPPC SPL Pin Joint / Pin Driven Pump

FEATURES

- Open Pin Joint

- Designed for Easy Maintenance

- Non-Pulsating Flow

- Low Vibration

- High Efficiency

- Viscosites Exceeding 1 Million Centipoise

Applications

Grout, Asphalt, Lubricants, Pulp & Paper, Crude Oil, Soaps & Detergents, Clays, Drilling Muds

Optional Features

- Water Flush Packing

- Large Selection of Drive End Options

Brochures

Download

Download

MANUALS

Download

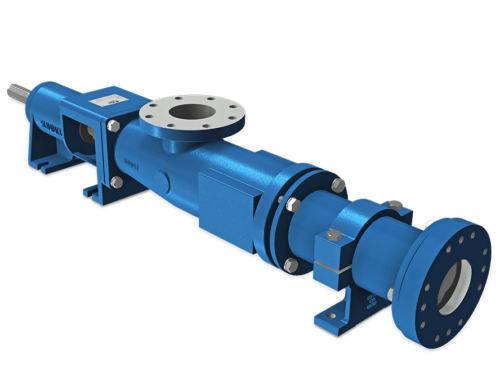

SPPC Gear Joint / Sealed Gear Joint Pump

FEATURES

- Sealed Gear Universal Joint

- Exceptional Abrasion Resistance

- Modular Design

- Ability to Rotate the Suction Housing

- Simple Design: Minimal Parts

APPLICATIONS

- Municipal Sludge

- Raw Sewage

- Adhesives

- Starch

- Crude Oil

- Plaster

- Resins

- Hazardous Wastes

- Paint

Optional Features

- Water Flush Packing

- Deflector near Rotor Head

- Shaft Sleeves

- Large Selection of Drive Ends

Brochures

Download

Download

Manuals

Download

SP1000 / Sealed Pin Joint Pump

The SP1000 series is an efficient, easy to maintain and versatile pump line ideal for highly viscous progress cavity applications.

Features

- Sealed Gear Universal Joint

- Exceptional Abrasion Resistance

- Modular Design

- Ability to Rotate the Suction Housing

- Simple Design: Minimal Parts

Applications

Paper Stock, Coating, Starch, Crude Oil, Lubricants, Soaps, Detergents, Paint, Polymer Transfer, Wastewater Treatment, Drilling Muds, Oil/Water Separations, Lime Slurries, Sampling, Polymer Metering, Pastes, Gels, Clay, Adhesives, Mastics, Mortar and Grout.

OPTIONAL FEATURES

- Variety of drivers and mounting configurations

- Packing or mechanical seals

Brochures

Download

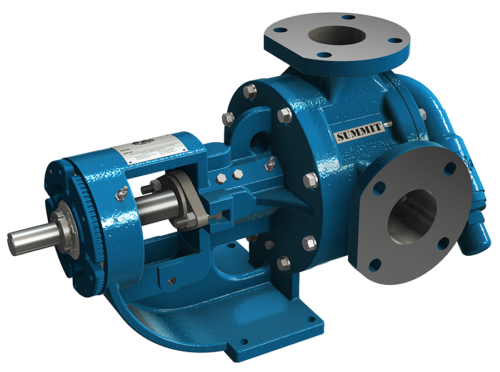

VV40 / Internal Gear Pump

FEATURES

- High Viscosity Fluid Capabilities

- High Abrasives Handling Ability

- Capacities to 470 GPM

- Pressures to 200 PSI

- Temperatures -60°F to 800°F

- External End Clearance Adjustment

- Self-Priming

- Available Packed or Mechanically sealed

- Interchangeable Parts between Specific Sizes

Applications

Water, Chemical, Oil, High Abrasive, Paint, Pulp and Paper, Resins/Adhesives

Optional Features

- Available without Safety Relief Valve

- Multiple Sealing Options

- Packed

- Component Mechanical Seal

- Cartridge Mechanical Seal

- Adaptability for Different Configurations

Brochures

Download

Manuals

Download

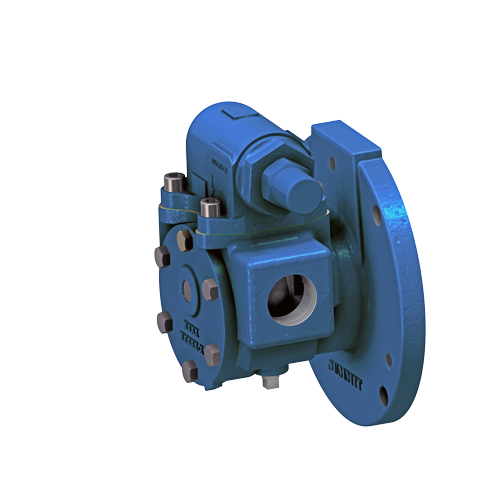

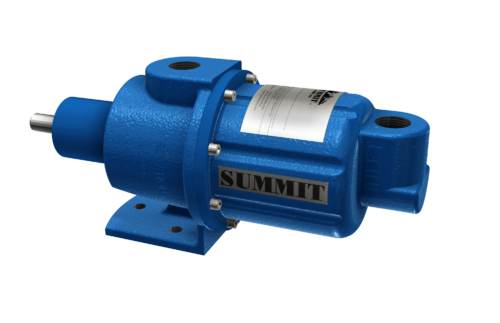

VV75 / Internal Gear Pump

FEATURES

- Compact Design is Simple to Mount

- Reduces Extensive Alignment Time

- Minimal Moving Parts

- High Viscosity Fluid Capabilities

- High Abrasives Handling Ability

- Capacities to 30 GPM

- Pressures to 100 PSI

- Temperatures -60°F to 225°F

- Self-Priming

- Available with lip or mechanical seal

- Interchangeable Parts between Specific Sizes

Applications

Water, Chemical, Oil, High Abrasive, Paint, Pulp and Paper, Resins/Adhesives

Optional Features

- Adjustable Safety Valve Settings (50 PSI standard)

- Available without Safety Relief Valve

- Multiple Sealing Options

- Lip Seal

- Component Mechanical Seal

- Adaptability for Different Configurations

Brochures

Download

Manuals

Download

VV95 / Internal Gear Pump

FEATURES

- High Viscosity Fluid Capabilities

- Ability to Operate at Higher Speeds

- Capacities to 115 GPM

- Pressures to 250 PSI

- Temperatures -40°F to 350°F

- External End Clearance Adjustment

- Self-Priming

- Mechanically sealed Behind Rotor, Isolating Bearings from Fluid

- Interchangeable Parts between Specific Sizes

- 180 Degree NPT Suction and Discharge Ports

- Integrated Gauge Ports

Applications

Water, Chemical, Oil & Fuel, High Abrasive, Paint, Pulp and Paper, Resins/Adhesives

Optional Features

- Available with or without Safety Relief Valve

- Adaptability for Different Configurations

Brochures

Download

Manuals

Download

SPPC Wobble / SWP & SWPM

FEATURES

- Multiple Material Options

- Simple and Compact

- High Solids Pumping Ability

- Self-Priming: Suction Lifts to 26 Feet

- Smooth Continuous Operation

- Quiet Operation

- Rotors & stators SWP15, SWP22, SWP33 & SWP44 are interchangeable, along with SWPM rotors & stators

Applications

Water, Abrasives, Waster & Water Treatment, Oils and Lubricants, Polymers, Bilge Pump, Mobile Friendly Applications, Chemical Slurries, Irrigation, Limestone Slurries, Paint

Brochures

Download

Manuals

Download

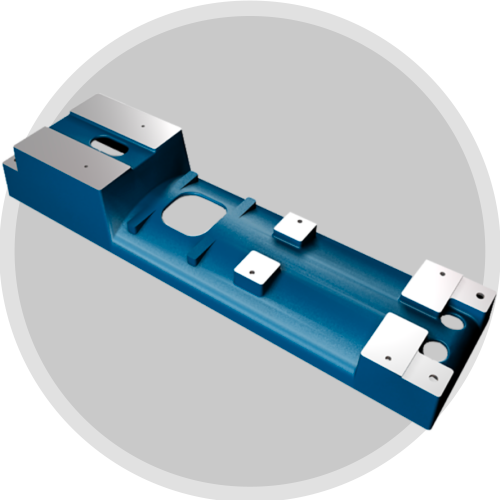

Base Plates/Guards

FEATURES

- ANSI B73.1 M Dimensions

- Excellent Corrosion Resistance

- Vibration Dampening: Superior to Steel and Iron

- Integrally Molded Catch Basin

- 304 Stainless Steel Inserts

- Barrel type coupling guards will bolt directly to many common models of pumps including: Goulds®, Durco®, Summit™, Peerless® and others.

Optional Features

- Custom Sizes

- Custom Colors

- Hastelloy-C Inserts

- Leveling Screws

- Compatible Grout

- Integrally Molded Grout Holes

FEATURES

- Economically Priced

- Available in Safety Yellow or Safety Orange

FEATURES

- ANSI B73.1 M dimensions

- Base Plates in stock

- Custom base plates, fabricated only

- Painted

Optional Features

- Multiple materials for fabricated base plates

- Drill and tap options