Equipment Survey

Knowing the manufacture and model number of the mechanical seals and pumps at your plant is imperative when managing your plant. Carolina Seals offers an Equipment Survey program in which we will collect important data about equipment such as but not limited to: Equipment ID and service name, Type and mfg of mechanical seal, Single seal or Double seal, API piping plan, standard bore or large bore seal chambers, pump Mfg and Model #s, bearing isolators or lip seals, oil bath or grease, motor frame size, Horse power, & rpms. With help from the plant we can determine how critical each piece of equipment is and create an Excel spreadsheet listing the collected data. This spreadsheet will aid you in determining the following: Troubleshooting issues with pump & sealing specialist, Inventory of pump parts and mechanical seals, Establishing the average Mean Time Between Failure of your equipment and Identify bad actors.

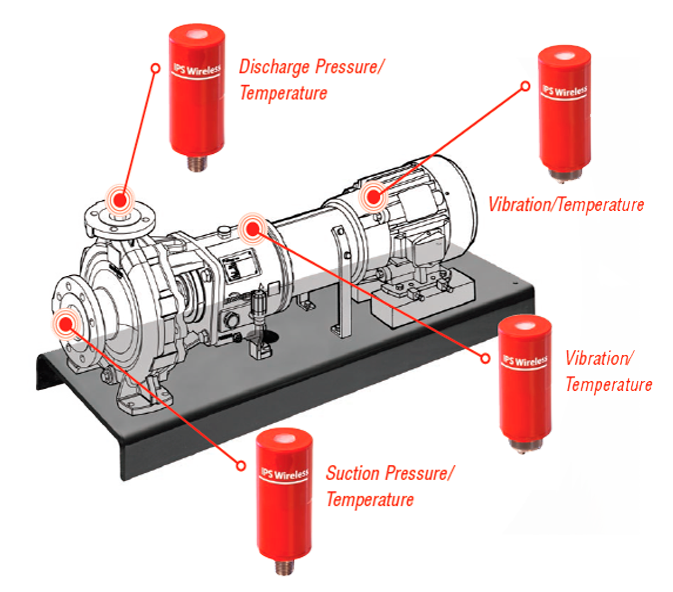

IPS Wireless Vibration Monitoring

Through the application of advanced technologies, the Flowserve Intelligent Process Solutions (IPS) Family of products helps customers proactively manage their plant assets to increase plant uptime and reduce equipment life cycle costs. Flowserve offers advanced monitoring solutions- wired and wireless – for permanent and portable data collection and analysis of vital assets. Monitoring and control solutions from Flowserve are engineered specifically to address process and equipment issues. As a result, user interfaces are highly intuitive and information is easy to interpret and immediately actionable. In addition, Flowserve is on the leading edge of predictive monitoring and diagnostics. Onboard sensors and intelligent algorithms make it possible for plant operators to predict system behavior before failure or disruption, thus protecting their most critical plant assets.

Laser Alignment

Shaft alignment is critical in prolonging the life of your mechanical equipment. Misalignment occurs when the centerlines of the motor and the driven equipment shafts are not in alignment with each other. Incorrect alignment creates excessive vibration, noise, coupling wear, increased bearing temperature, and premature bearing, coupling and or mechanical seal failure. We offer Laser Alignment using our Vibralign system.

Seal Failure Analysis

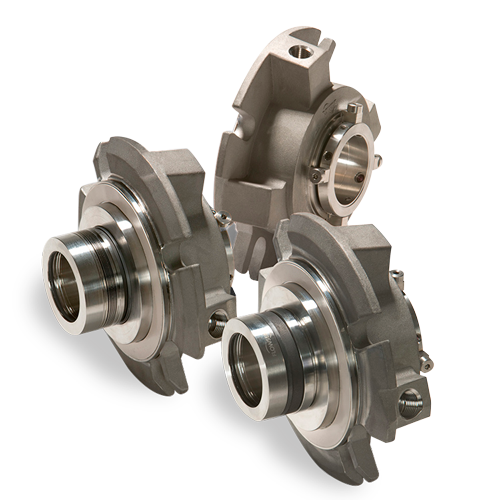

If you change out a failed seal without knowing why it failed, you could be jeopardizing the life of the replacement seal. Very few mechanical seals reach their designed life expectancy. Bad bearings, bent shafts, dry running conditions, and worn equipment all decrease the life of your mechanical seal. There are several ways in which we help identify your failure mode. Flowserve offers a Seal Failure Analysis Guide which can be downloaded on your cell phone or tablet. This guide walks you through examining the induvial parts of your mechanical seal through 100’s of pictures of damaged faces, o-rings, & metal parts. Once you find the picture that looks like your damaged, you will be given a list of possible causes and correction. Next, Carolina Seals can send one of our trained Sealing Specialist to your site to help troubleshoot your sealing issue by using years of experience gained by dealing with pump and seal issues. Lastly, Flowserve offers in depth seal failure analysis at their Florence, SC QRC (Quick Response Center).

QRC Repair Shop

Flowserve’s Quick Response Centers are strategically located to ensure that a QRC is within hours of most major industrial customer locations. This allows rapid response to customer needs by providing a local repair facility that is focused on quick repair turnarounds. With the help of Flowserve QRCs, plant managers are able to maximize plant uptime and profitability.

Competitor Changeout Program

Mechanical Seals are our livelihood and there are multiple mechanical seal manufacturers for end users to choose from. Carolina Seals tries to differentiate ourselves from our competition by offering additional services such as Equipment Surveys, Establishing a “Bad Actor List”, Vibration Monitoring, Pump & Seal Training, Troubleshooting, as well as we stock one of the largest inventories of Flowserve seals in the region. So in the past, changing seal manufactures would require our customers to throw away their old mechanical seal and purchase a new Flowserve mechanical seal. We’ll not anymore. Flowserve offers a competitor exchange program in which you can trade out a used seal for a new Flowserve seal at repair cost. So you as a customer are not penalized by changing seal manufacturers.

Education & Training

Flowserve Educational Services provides companies around the world with a wide range of innovative programs focused on helping plant operators, reliability engineers and maintenance personnel deepen their understanding of pumping systems. Training programs from Flowserve are ideal for organizations aiming to achieve: • Maximized plant asset availability and equipment reliability • Increased mean time between repair (MTBR) • Workforce development for increasing proficiency in the installation, maintenance, and repair of pumping equipment and systems.

Carolina Seals offers in plant half day and full day pump & seal training catered to the equipment you have installed at your plant. Using videos, power point slides, and pump & seal samples, we will teach proper methods of successfully rebuilding, installing and operating pumps and mechanical seals at you plant.

FLOWSTAR

Flowstar.net is a web-based maintenance management tool that helps you improve the reliability of your business assets by tracking work orders, maintenance, and asset configuration details. When paired with our Lifecycle Advantage program (LCA), Flowstar.net enables onsite engineers to make process improvement recommendations and track results.

Kunkle Safety and Relief Valve Repairs

Carolina Seals offers Safety and Relief Valve Repairs by a local certified repair facility.