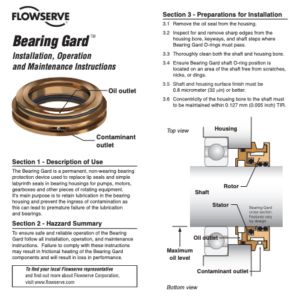

Why use a Bearing Gard?

Extend the life and improve reliability of rotating equipment with the Bearing Gard

- Eliminate #1 cause of rotating equipment failure

- Prevent contamination ingress

- Extend oil and bearing life

- Provide long term oil retention

- Add protection at shutdown

- Shut-ff O-ring blocks air transfer

- Create a positive return on investment

- Improved maintenance, housekeeping and safety

- An average investment of $500 per pump or motor can prevent maintenance or repair costs of $5,000 – $20,000 and more

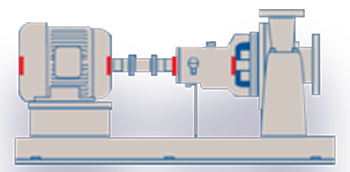

Where do I use the Bearing Gard?

Pumps: ANSI, ISO, API 610 and more

All types of non-flooded bearing seals in rotating equipment

Gearboxes: non-flooded oil lubrication and grease

Specialty applications: steam turbines, pillow blocks and more

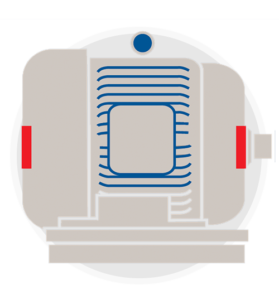

Electric Motors

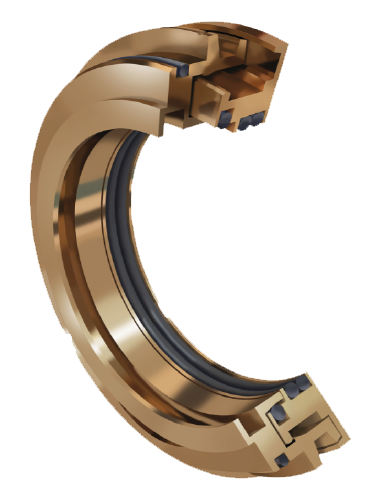

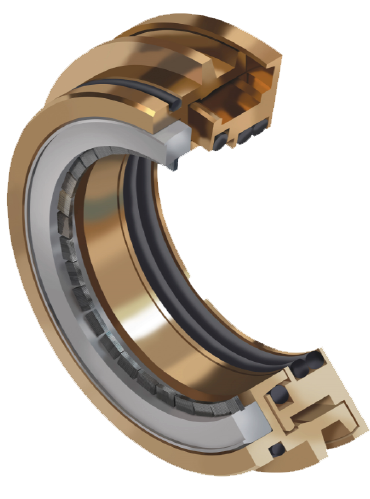

Bearing Gard Key Features

- Innovative shut-off design

- Improved static sealing

- Tapered shoulder creates positive wall sealing at all times

- Dynamic lifts off to prevent wear at operational speed

- Increased reliability by preventing O-ring binding

Bearing Gard Products

Bearing Gard

Bearing Gard

With Electrical Grounding

Custom sleeve

bearing designs

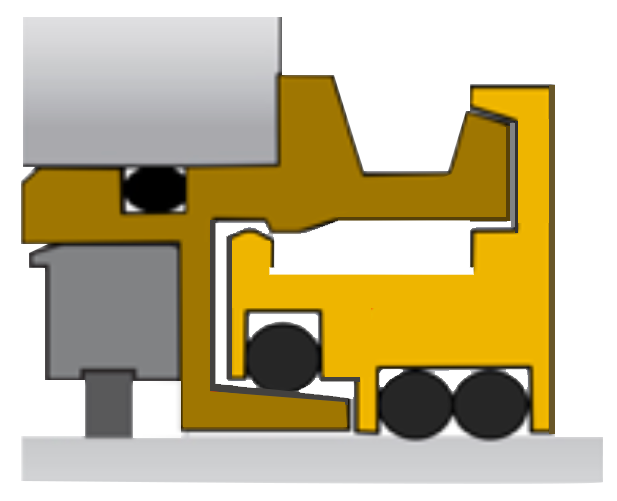

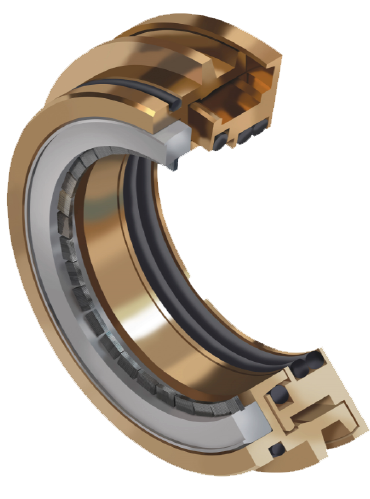

Bearing Gard with AEGIS Grounding Device

Complete motor protection

The growing population of Variable Frequency Drives (VFDs) as motor controllers has revealed electrical grounding through the bearings to be a major cause of premature motor failure. The Bearing Gard with electrical grounding is specifically designed to prevent motor failure from electrical fluting and contamination ingress. AEGIS bearing protection ring utilizes Electron Transport Technology and conductive microfibers to provide the most reliable current diversion.

Key Features

- Located at the 12 o’clock position

- 180 degrees from outlet ports

- Customer requested feature

- Helps orientation for installation

- Easy check for proper assembly