Pulp & Paper

Pulp & Paper

Pulp & Paper

Pulp & Paper

Traditionally, pulp and paper mills have used compression packing to limit leakage from centrifugal pumps and other rotating equipment. But mechanical seals are being used more and more because of their reliability and ability to reduce operating costs. The long term savings resulting from trouble-free performance, water conservation,less downtime, lower maintenance costs, energy conservation, and health/safety/pollution control with Flowserve Seals are significant. So even through compression packing may be less expensive to purchase, it costs you more than you think. Mechanical seals make even more sense when handling the array of liquids common in chemical pulping, bleaching, and paper making. These services are tough on pumps and other rotating equipment because of the caustics, abrasives, and liquors.

Pulp & Paper

Traditionally, pulp and paper mills have used compression packing to limit leakage from centrifugal pumps and other rotating equipment. But mechanical seals are being used more and more because of their reliability and ability to reduce operating costs. The long term savings resulting from trouble-free performance, water conservation,less downtime, lower maintenance costs, energy conservation, and health/safety/pollution control with Flowserve Seals are significant. So even through compression packing may be less expensive to purchase, it costs you more than you think. Mechanical seals make even more sense when handling the array of liquids common in chemical pulping, bleaching, and paper making. These services are tough on pumps and other rotating equipment because of the caustics, abrasives, and liquors.

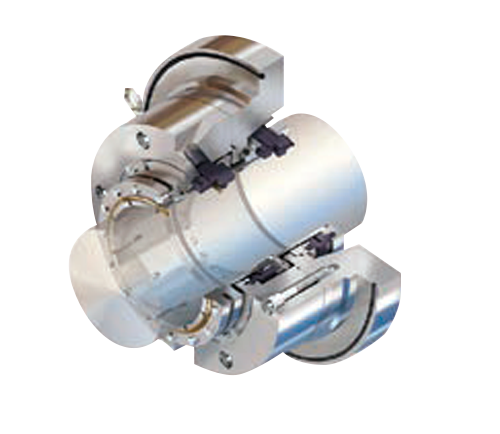

The Series 80 seal is one of Flowserve’s Heritage products that has a proven track record of performance. Built with premium materials, this Stationary designed, Hydraulically balanced seal succeeds in the most challenging applications.

Flowserve spun off the more popular sizes of the Series 80 and formed the CPM seal which allows us to compete with today’s low cost seal manufacturers. The CPM line of seals are used for competitor change outs in general service applications. Compared to other light duty seals, the CPM seal weights 30% more due to the heavy duty gland design. The flush port is also larger than most light duty seals making the CPM seal a better all-around choice.

SPECIFICATIONS

Press. to vacuum to 400 psig (27 bar)

Temp: -40 to 400 F (-40 to 204 C)

Speeds to: 100 ft/min (30m/s)

Sizes: 3/4″ to 3.750″

FEATURES & BENEFITS

- Robust rotary face design is flexibly mounted, enhancing the ability to survive shock and face distortion typically found in clamped seal face designs.

- Springs located outside the process fluid deter chemical stress corrosion and spring clogging by dirty process fluids.

- Hydraulically balanced seal design reduces friction, heat and wear with lower loading forces while maintaining a lubrication film between the mating faces.

- Floating stationary to accommodate out-of-square pump misalignment.

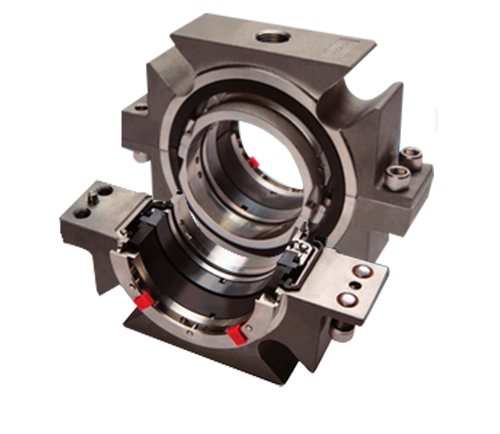

The PSS 4 semi-cartridge split seal is ideal for pump and mixer applications. With only two major components, it makes installation quick and easy without requiring equipment teardown.

SPECIFICATIONS

Press.: Vacuum to 30 bar (450 psi)

Temp: -18°C to 121°C (0°F to 250°F)

Speeds: to 19.3 m/s (3800 fpm)

Sizes: 38 to 152 mm (1.500 to 6.000 in); contact Flowserve for larger sizes

FEATURES & BENEFITS

- Exclusive 3D Key technology assures optimum face alignment in both axial and radial direction, reducing leakage and installation time

- Unique setting tabs eliminate all seal positioning, measuring and marking, assuring installation success

- Easily handles mixer equipment runout up to 1.5 mm (0.060 in) TIR radial shaft movement

- Fully split design installs easily around the shaft, outside the seal chamber, eliminating the need to dismantle the equipment

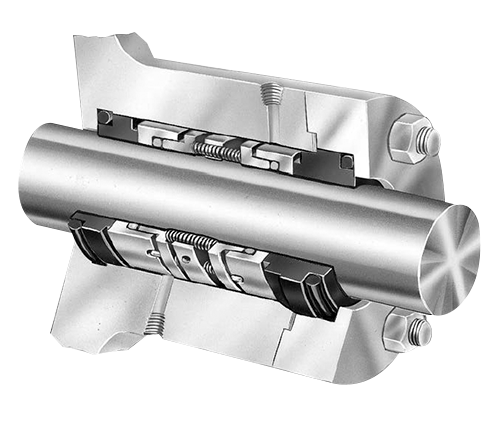

This single, unbalanced, multi-spring component seal is usable as an inside or outside mounted seal. Suitable for abrasive, corrosive and viscous fluids in chemical services.

specifications

Pressure: to: 20.7 bar (300 psi)

Temperature: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Increased durability from robust rotating spring compression unit that helps to keep solids away from the seal faces and removes seal-generated heat

- Improved reliability with rotating seal ring that is independently centered on the shaft and has multiple springs and drive pins that evenly distribute the load

- Broad application flexibility enabled by completely interchangeable shaft packing materials, dimensionally interchangeable insert mounting, and compression unit availability in any machinable metallurgy

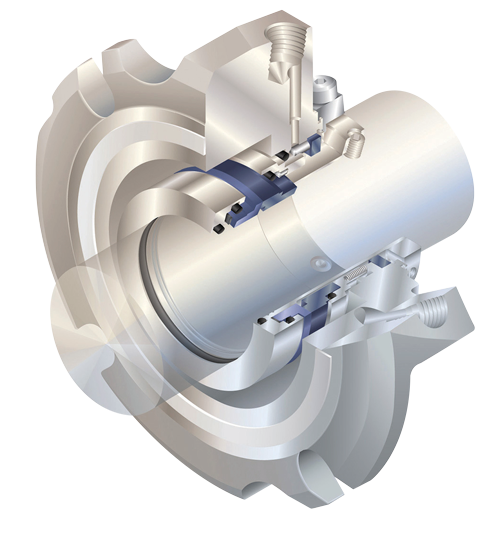

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

specifications

Pressure: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: pusher 25 to 200 mm (1.000 to 8.000 in); bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

specifications

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

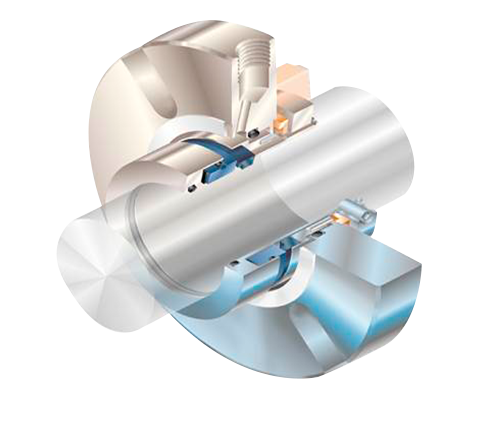

The balanced single cartridge pusher seals has a flexible stator and operates without outside flush liquid to eliminate product dilution, increase plant efficiency and reduce costs.

SPECIFICATIONS

Pressure: to: 17.2 bar (250 psi)

Temperature: -40°C to 149°C (-40°F to 300°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 50 to 235 mm (2.000 to 9.250 in)

FEATURES & BENEFITS

- Increased reliability and consistent “no visible leakage” operation due to line-on-line, hydraulically balanced faces

- Extended seal life enabled by centroid-loaded monoblock rotor that helps to maintain zero net deflection, reducing leakage and wear

- Reduced maintenance costs provided by large cross-section stator O-ring, which allows maximum shaft movement while reducing the damaging effects of hang-up

- Dependable performance provided by single seals handling solids to 20%, dual seals to 60% solids, and quench options providing complete application flexibility

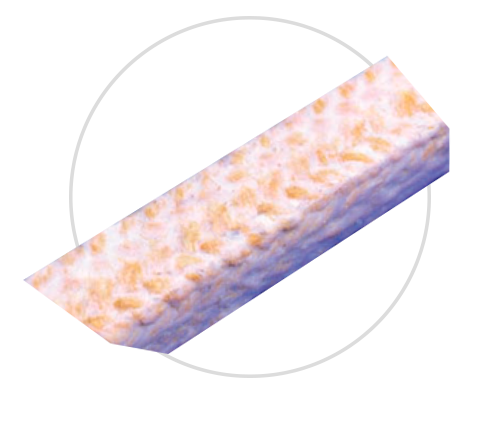

Construction: Multi-Lok Braid

specifications

Shaft speeds to 3600 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

- PTFE/Graphite composite yarn for wide ranging plant applications including aggressive fluids and high temperatures.

- Equipment: Pumps, agitators and mixers

- Recommended For: All corrosive applications suitable for PTFE and graphite.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 4400 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

- Made of 100% PTFE material, Flexible Lantern Material is an innovative approach to standard lantern rings, flexible lantern material is easier to install and remove.

- Sold in roll form like bulk packing, flexible lantern ring material can be cut to the specific length needed, therefore eliminating the need to stock many different size rings.

- Speeds up repacking because it is pliable enough to be removed easily

- Eliminates stock of many different materials because the PTFE material is designed for a wide variety of applications

GFO® is a registered trademark of W.L. Gore and Associates

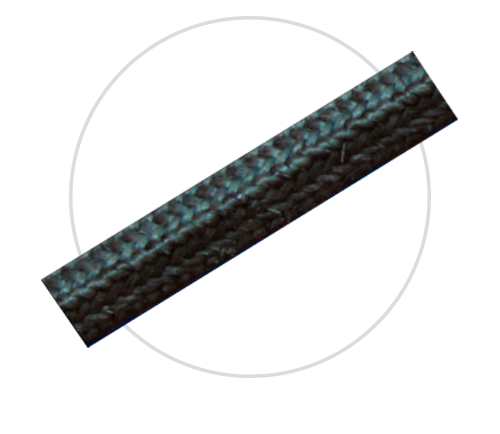

Construction: Multi-Lok Braid

SPECIFICATIONS

Shaft speeds to 4000 FPM

temperatures to 650°F/345°C

pH range 0-14 except in strong oxidizers.

SOME TYPICAL APPLICATIONS INCLUDE:

- High strength yarns with high thermal conductivity and lubricity.

- Equipment: General service on rotary and reciprocating equipment including high speed pumps and slurry service.

- Recommended For: Pumps and agitators in pulp and paper, mining and other process industries.

- ML560’s high thermal conductivity and lubricity allow it to operate without flush water in some applications.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 1885 FPM

temperatures to 550°F/288°C

pH range 3-12

FEATURES & BENEFITS

- A proprietary blend of non-asbestos TEK-PRO yarns treated with PTFE throughout the packing. The PTFE suspensoid thoroughly seals and fills all voids providing better resistance to chemical attack.

- A light lubricant is applied under pressure to improve run-in properties.

- Equipment: Rotating and reciprocating pump and valve equipment, mixers and agitators.

- Recommended For: Pulp and paper mill applications, recovery pumps, chemical applications, caustic soda.

- An excellent all-around general service chemical packing.

- The TEK-PRO yarns retain a greater volume of PTFE dispersion and are more uniformly distributed to provide longer and better sealing.

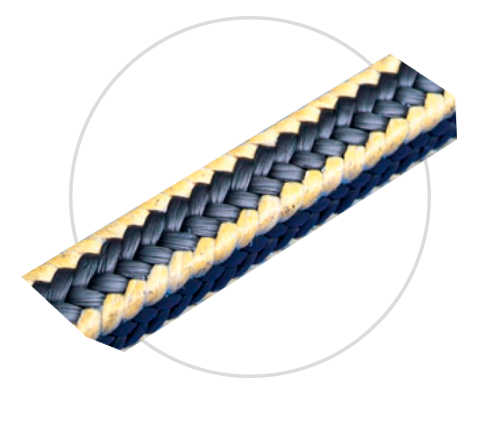

Construction: Multi-Lok Braid

specifications

Shaft speeds to 2500 FPM

temperatures to 500°F/260°C

pH range 3-11

FEATURES & BENEFITS

- A combination braid of PTFE/Graphite composite yarn and aramid fibers.

- This construction provides the strength of aramid fibers and the heat dissipating and lubricating qualities of the PTFE and graphite matrix.

- Treatment: Light coat of an inert break-in oil.

- Equipment: Paper mill stock pumps, agitators, or any service where strength and good lubricating qualities are needed.

Construction: Multi-Lok Braid

SPECIFICATIONS

Shaft speeds to 4000 FPM

temperatures to 850°F/454°C in oxidizing conditions

Temperatures to 1200°F/649°C in steam

pH range 0-14 except strong oxidizers.

SOME TYPICAL APPLICATIONS INCLUDE:

- Pure homogenous graphite bonded to a fiberglass carrier for strength and thermal stability.

- It has no added lubricants or binders to cook out or become brittle.

- Treatment: None.

- Equipment: Pumps and valves, volatile organic chemical service.

- Recommended For: Rotating shafts where high shaft speeds and thermal conductivity are required.

- Note: For valve service Styles ML2001Z with zinc corrosion inhibitor and ML2001P with a passivating corrosion inhibitor are available.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 3000 FPM

temperatures to 600°F/345°C

pH range 0-14.

FEATURES & BENEFITS

- ML 4461 Carlon is a carbon filament packing treated with PTFE to help prevent color contamination and carbon migration.

- Treatment: Each strand of the carbon yarn is treated and impregnated with a PTFE suspensoid, totally encapsulating the packing to prevent carbon filaments migrating into the system.

- Equipment: Pulp mill equipment, steaming vessels, top separators, refiners, outlet devices, blow pumps, stock pumps, agitators and valves.

- Recommended For: Most chemical services, except strong oxidizers.

specifications

Temperatures to 550°F

pH range 0-14.

FEATURES & BENEFITS

- Made of 100% PTFE material, Flexible Lantern Material is an innovative approach to standard lantern rings, flexible lantern material is easier to install and remove.

- Sold in roll form like bulk packing, flexible lantern ring material can be cut to the specific length needed, therefore eliminating the need to stock many different size rings.

- Speeds up repacking because it is pliable enough to be removed easily

- Eliminates stock of many different materials because the PTFE material is designed for a wide variety of applications

Tetracord is a universal joint sealant manufactured from 100% expanded PTFE and combined with a self-adhesive strip for easy application. It forms a quick, but permanent seal on anything from a pipe joint to a manhole cover.

SPECIFICATIONS

Pressure up to 3000 psi

Temp up to 600 F

pH Range: (all fluids except free fluorine and molten alkali metals)

FEATURES & BENEFITS:

- Adhesive backing for easy installation, is soft and flexible so it handles curves and contours.

- It is sold in continuous cord form so you only cut off what you need each time.

- Installation takes only minutes, and removal of the sealant is simple and involves no scraping, which saves downtime and money.

- Strong, durable PTFE material has excellent chemical resistance to many

acids, alkalis, salts and organic chemicals. - It is also asbestos-free, non-toxic and noncontaminating, so it is a good sealant

choice for food, pharmaceuticals, and diagnostics applications. - Tetracord is also recommended for heavy duty applications such as high pressure steam turbine housings and fragile glass joints.

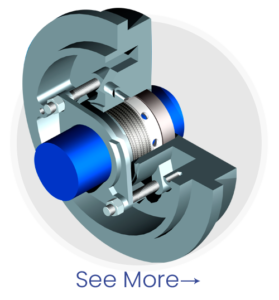

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements

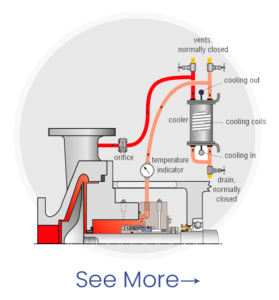

The Seal Gard manages seal water flow rates for single and dual seals to improve the mean time between planned maintenance of your rotary equipment by improving the environment in the seal area.

specifications

Flows to: 13 lpm (3.5 gpm)

Press. to: 25 bar (363 psi)

Temp: 0°C to 100°C (32°F to 212°F)

FEATURES & BENEFITS

- Lower operating cost from dependable flow control that saves water costs by reducing seal water usage

- Ease of operation assured by clear-view acrylic flow meter with vertical flow tube that resists fouling and vibration-resistant pressure gauge

- Reduced downtime enabled by standard check valve that prevents backup of product into the seal water line in the event of pressure reversal