Chemical Industry

Chemical Industry

Chemical Industry

Chemical Industry

Aggressive corrosion and erosion. Hazardous, toxic substances. Application variation that makes equipment specification more than a little challenging. The chemical industry faces tough challenges, and Flowserve is in the middle of them, solving our customers’ most difficult hurdles every day. Our solutions span the industry, from basic, organic, specialty and fine chemicals to biofuels and pharmaceuticals. We continue to build on our materials science heritage and advance sealing and flow control technologies. We do this to help customers improve performance, maximize service life and keep personnel safe.

Chemical Industry

Aggressive corrosion and erosion. Hazardous, toxic substances. Application variation that makes equipment specification more than a little challenging. The chemical industry faces tough challenges, and Flowserve is in the middle of them, solving our customers’ most difficult hurdles every day. Our solutions span the industry, from basic, organic, specialty and fine chemicals to biofuels and pharmaceuticals. We continue to build on our materials science heritage and advance sealing and flow control technologies. We do this to help customers improve performance, maximize service life and keep personnel safe.

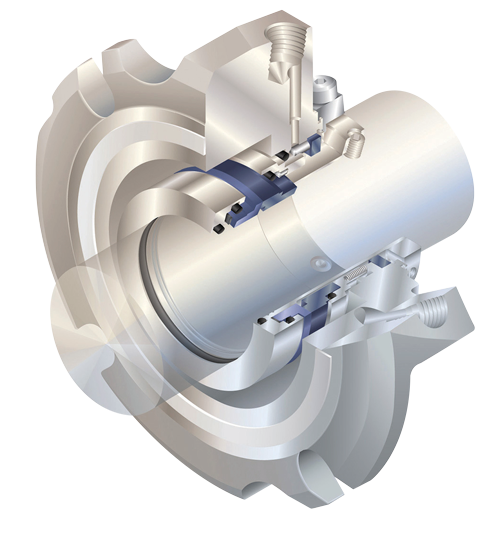

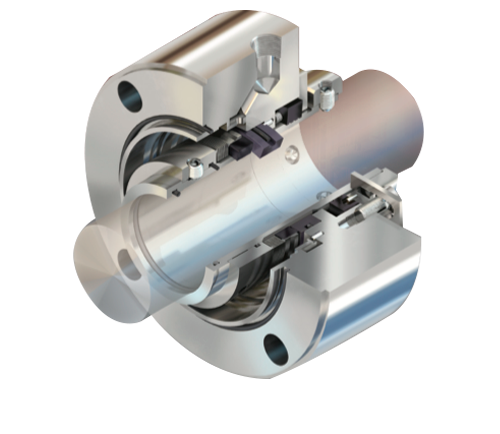

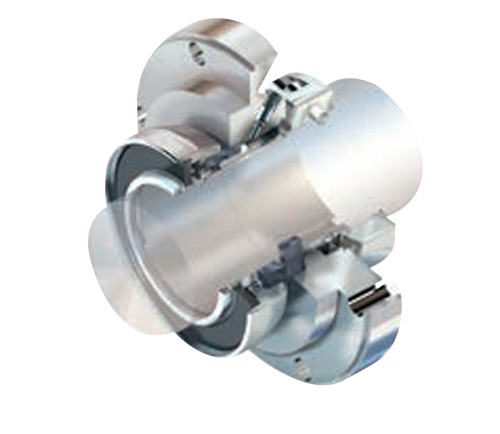

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

specifications

Pressure: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: pusher 25 to 200 mm (1.000 to 8.000 in); bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

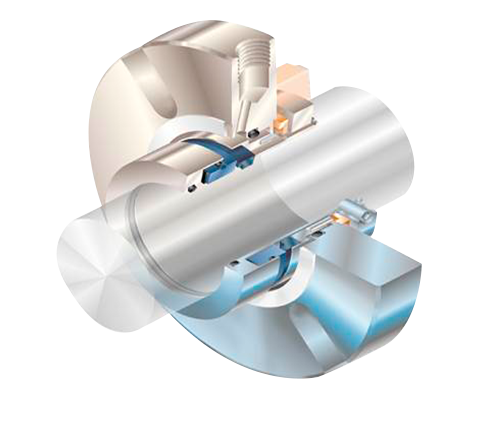

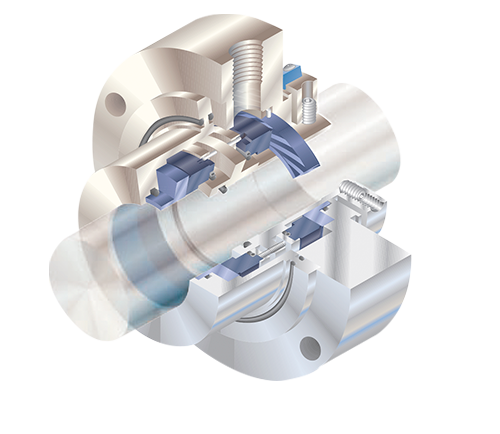

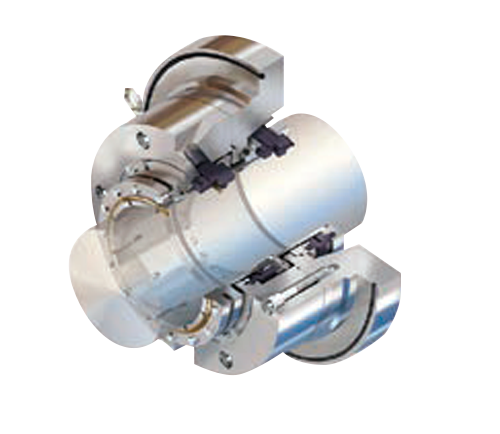

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

specifications

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

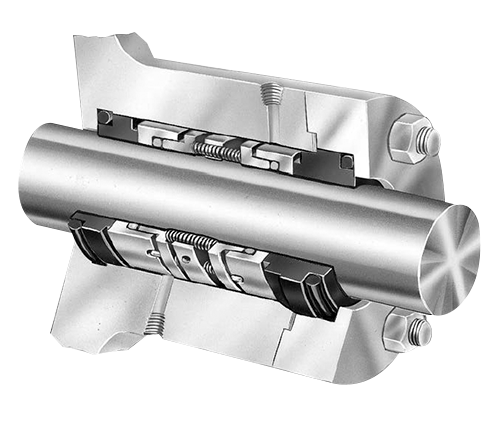

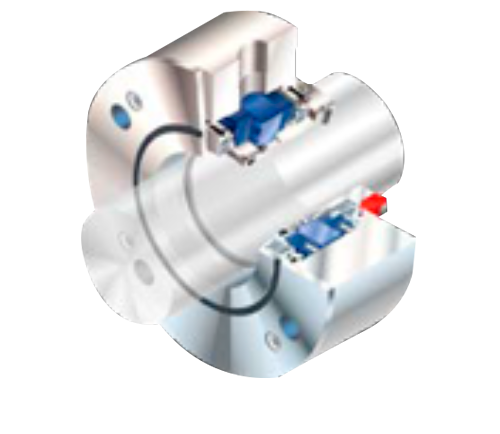

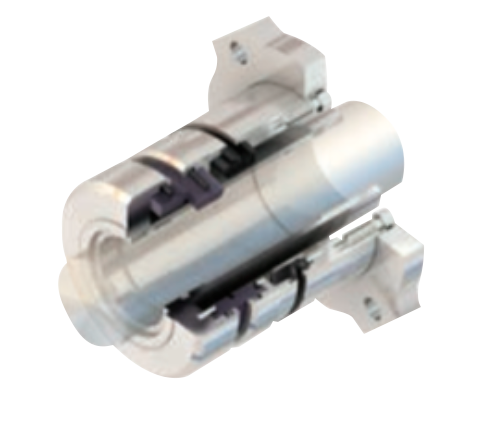

The Series 80 seal is one of Flowserve’s Heritage products that has a proven track record of performance. Built with premium materials, this Stationary designed, Hydraulically balanced seal succeeds in the most challenging applications.

Flowserve spun off the more popular sizes of the Series 80 and formed the CPM seal which allows us to compete with today’s low cost seal manufacturers. The CPM line of seals are used for competitor change outs in general service applications. Compared to other light duty seals, the CPM seal weights 30% more due to the heavy duty gland design. The flush port is also larger than most light duty seals making the CPM seal a better all-around choice.

SPECIFICATIONS

Press. to vacuum to 400 psig (27 bar)

Temp: -40 to 400 F (-40 to 204 C)

Speeds to: 100 ft/min (30m/s)

Sizes: 3/4″ to 3.750″

FEATURES & BENEFITS

- Robust rotary face design is flexibly mounted, enhancing the ability to survive shock and face distortion typically found in clamped seal face designs.

- Springs located outside the process fluid deter chemical stress corrosion and spring clogging by dirty process fluids.

- Hydraulically balanced seal design reduces friction, heat and wear with lower loading forces while maintaining a lubrication film between the mating faces.

- Floating stationary to accommodate out-of-square pump misalignment.

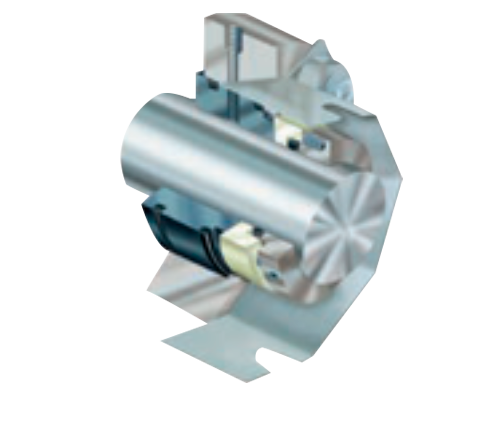

This single, unbalanced, multi-spring component seal is usable as an inside or outside mounted seal. Suitable for abrasive, corrosive and viscous fluids in chemical services.

SPECIFICATIONS

Pressure: to: 20.7 bar (300 psi)

Temperature: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Increased durability from robust rotating spring compression unit that helps to keep solids away from the seal faces and removes seal-generated heat

- Improved reliability with rotating seal ring that is independently centered on the shaft and has multiple springs and drive pins that evenly distribute the load

- Broad application flexibility enabled by completely interchangeable shaft packing materials, dimensionally interchangeable insert mounting, and compression unit availability in any machinable metallurgy

The CRO is an economical, single-coil spring, friction drive component seal for use in pumps with packing box seal chambers. Available in single or dual arrangements.

specifications

Press. to: 20.7 bar (300 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Longer service life derived from rotating seal ring that self-centers around the shaft and withstands the harsh demands of cyclic operation or continuous duty

- Increased durability from robust single-coil spring that resists clogging and chemical attack

- Simplified installation and improved corrosion resistance due to a design with a minimum number of seal components with heavy cross-sections

With its composite rotor, the RA single outside-mounted component seal is a cost-effective solution for highly corrosive chemical services. Suitable for metallic and nonmetallic equipment, such as plastic, glass and lined designs.

specifications

Press. to: 27.6 bar (400 psi)

Temp: -40°C to 177°C (-40°F to 350°F)

Speeds to: 23 m/s (75 fps)

Sizes: 13 to 127 mm (0.500 to 5.000 in)

FEATURES & BENEFITS

- Installation ease with design that attaches to the outside of the seal chamber

- Corrosive application performance and flexibility provided by seal faces and elastomers in diverse materials, plus non-wetted drive collar, springs and drive pins on the RA-C configuration to avoid the need for expensive alloys

- Greater reliability assured by flexible rotor design, hydraulically balanced to provide proper face loading

- Better process control via double O-ring mounted stator that prevents distortion

BX Series balanced rotating metal bellows seals provide exceptional reliability in corrosive and non-corrosive fluids, especially those that crystallize. Fully compliant with API 682 Type B, Arrangements 1, 2 and 3.

specifications

Pressure: to: 27.6 bar (400 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 12.3 to 127 mm (0.483 to 5.000 in)

FEATURES & BENEFITS

- Longer service life with 0.20 mm (0.008 in) thick standard welded metal bellows for resistance to corrosion, shaft vibration and centrifugal forces

- Optimal performance ensured by three standard seal face balances; the BXQ seal is high balanced for flashing hydrocarbon applications

- Increased maintenance intervals due to self-cleaning rotating bellows that replace springs and dynamic elastomers

- Performance benefits of metal bellows in dual pressurized Arrangement 3 seals with the BXB seal’s unique ID pressurized seal face balance

Built for temperatures beyond the limits of elastomers, the BXRH balanced stationary metal bellows seal offers reliable sealing at high speeds. Meets all API 682 Type C requirements in Arrangements 1, 2 and 3.

specifications

Press. to: 20.7 bar (300 psi)

Temp: -73°C to 427°C (-100°F to 800°F)

Speeds to: 46 m/s (150 fps)

Sizes: 21.8 to 127 mm (0.857 in to 5.000 in)

FEATURES & BENEFITS

- Optimal performance resulting from flexible graphite gasketing in lieu of elastomers to improve temperature and chemical compatibility

- Reliability due to extra-long Alloy 718 bellows that offer superior corrosion resistance, allow more axial travel, and provide consistent spring loading

- Application flexibility arising from single and dual seal configurations as well as pressurized and unpressurized arrangements

- Reduced clogging due to absence of springs and dynamic elastomers, plus standard anti-coke device

This dual pressurized non-contacting, gas barrier pusher seal is used in applications where zero emissions of hazardous pumped products can be tolerated.

SPECIFICATIONS

Press. to: 34.5 bar (500 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds: 1.3 to 25 m/s (4 to 82 fps)

Sizes: 25.4 to 152 mm (1.000 to 6.000 in)

FEATURES & BENEFITS

- Environmental regulatory compliance assured by inert gas barrier that operates with zero process emissions

- Greater reliability enabled by spring energized O-ring technology to maintain proper seal face tracking

- Longer service life from silicon carbide seal faces using APG precision face topography, which creates a stiff, thin gas film that prevents wear

- Economical performance via non-contacting seal faces that require very low power consumption during startup and operation

GX-200 dual metal bellows seals utilize APG non-contacting seal face technology for outstanding performance in a variety of applications. Fits standard or small bore seal chambers without modifications.

SPECIFICATIONS

Press. to: 13.8 bar (200 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds: 2.5 to 35 m/s (8 to 115 fps)

Sizes: 25.4 to 76.2 mm (1.000 to 3.000 in)

FEATURES & BENEFITS

- Environmental regulatory compliance assured by inert gas barrier that operates with zero process emissions

- Long-term reliability provided by high alloy metal bellows that resist contamination and hang-up while providing pressure reversal product containment during upset events

- Lower operation and maintenance costs provided by unique design that eliminates the costs of maintaining a liquid barrier system and the risks of barrier fluid contamination

- Economical performance enabled by energy-efficient design that delivers the industry’s lowest power consumption for conventional pumps

The BRO Seal was designed for large diameter mixer shafts. The unique design allows a large cross-section of carbon to be used as a seal ring, so that the rotating carbon face can be assembled in the rotary unit by the seal manufacturer.

SPECIFICATIONS

Press. up to 400 psig (27 bar)

Temp: up to 250 F (121 C)

Speeds to: 3500 fpm (18m/s)

FEATURES & BENEFITS

- Flowserve designed the BRO seal to handle shaft movement found in larger shaft sized equipment.

- Maximum flexibility of the rotating seal is achieved because the carbon seal ring can float within the shroud.

- Balanced version is called BPO

- Seal is designed to fit most OEM housings.

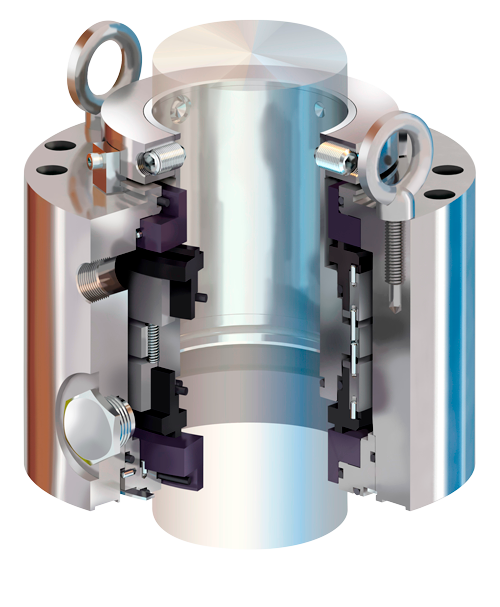

M Series vertical shaft mixer seals easily adapt to changing production requirements. They are designed for use with mixers, agitators, filters and dryers as well as steel- or glass-lined vessels.

specifications

Press: vacuum to 35 bar (500 psi)

Temp: to 200°C (390°F)

Speed: to 10 m/s (33 fps)

Sizes: 40 to 220 mm (1.575 to 9.000 in)

FEATURES & BENEFITS

- Unprecedented application flexibility provided by cartridge canister design that enables the seal faces to be changed out to run wet (MW), dry contacting (MD) or dry non-contacting gas barrier technology (ML)

- True component standardization with reduced inventory carrying costs owing to a high degree of parts interchangeability across the product line

- Optional materials compliant with FDA CFR 21, USP Class VI, ADI Free Components and similar specifications

- Specialized solutions customized up to 480 mm (18.900 in) shaft size (MWC-200)

SLC seals are heavy-duty, single pusher cartridge seals built for the harshest slurry pump services found in mining, mineral and ore processing, and flue gas desulfurization. Suitable for solids to 60% by weight.

sPECIFICATIONS

Pressure: to: 20.6 bar (300 psi)

Temperature: -18°C to 110°C (10°F to 230°F)

Speeds to: 15 m/s (50 fps)

Shaft Sizes: 32 to 220 mm (1.250 to 8.661 in)

FEATURES & BENEFITS

- Lower operating costs ensured by unique non-clogging, encapsulated cone spring, which increases reliability and enables flushless operation

- Maximized equipment uptime provided by abrasion-resistant metal components and silicon carbide faces that extend seal life beyond that of slurry pump components

- Economical performance via clean, open design, which operates without flush water to reduce product dilution and eliminate flush water costs

- Ease of installation resulting from cartridge design that requires no special tools or bearing housing adjustments

The balanced single cartridge pusher seals has a flexible stator and operates without outside flush liquid to eliminate product dilution, increase plant efficiency and reduce costs.

SPECIFICATIONS

Pressure: to: 17.2 bar (250 psi)

Temperature: -40°C to 149°C (-40°F to 300°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 50 to 235 mm (2.000 to 9.250 in)

FEATURES & BENEFITS

- Increased reliability and consistent “no visible leakage” operation due to line-on-line, hydraulically balanced faces

- Extended seal life enabled by centroid-loaded monoblock rotor that helps to maintain zero net deflection, reducing leakage and wear

- Reduced maintenance costs provided by large cross-section stator O-ring, which allows maximum shaft movement while reducing the damaging effects of hang-up

- Dependable performance provided by single seals handling solids to 20%, dual seals to 60% solids, and quench options providing complete application flexibility

The RIS rubber-energized, component slurry seal features a unique non-clogging design that does not utilize springs or bellows. Handles solids to 50% by weight.

SPECIFICATIONS

Press. to: 10.3 bar (150 psi)

Temperature: -4°C to 110°C (25°F to 230°F)

Speeds to: 11 m/s (36 fps)

Shaft Sizes: 32 to 235 mm (1.250 to 9.250 in)

FEATURES & BENEFITS

- Ease of installation provided by innovative adaptive components that allow the seal to be installed from the wet end and adjusted externally

- Longer MTBF from non-clogging elastomer spring design that has no dynamic O-ring to hang up

- Reliable operation ensured by the rubber-energized stationary seal face that holds the seal faces together and absorbs relative shaft movement

- Reduced operating costs and improved control made possible by flushless operation, which is especially beneficial in flue gas desulphurization

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

specifications

Pressure: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: pusher 25 to 200 mm (1.000 to 8.000 in); bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

specifications

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

The Series 80 seal is one of Flowserve’s Heritage products that has a proven track record of performance. Built with premium materials, this Stationary designed, Hydraulically balanced seal succeeds in the most challenging applications.

Flowserve spun off the more popular sizes of the Series 80 and formed the CPM seal which allows us to compete with today’s low cost seal manufacturers. The CPM line of seals are used for competitor change outs in general service applications. Compared to other light duty seals, the CPM seal weights 30% more due to the heavy duty gland design. The flush port is also larger than most light duty seals making the CPM seal a better all-around choice.

SPECIFICATIONS

Press. to vacuum to 400 psig (27 bar)

Temp: -40 to 400 F (-40 to 204 C)

Speeds to: 100 ft/min (30m/s)

Sizes: 3/4″ to 3.750″

FEATURES & BENEFITS

- Robust rotary face design is flexibly mounted, enhancing the ability to survive shock and face distortion typically found in clamped seal face designs.

- Springs located outside the process fluid deter chemical stress corrosion and spring clogging by dirty process fluids.

- Hydraulically balanced seal design reduces friction, heat and wear with lower loading forces while maintaining a lubrication film between the mating faces.

- Floating stationary to accommodate out-of-square pump misalignment.

This single, unbalanced, multi-spring component seal is usable as an inside or outside mounted seal. Suitable for abrasive, corrosive and viscous fluids in chemical services.

SPECIFICATIONS

Pressure: to: 20.7 bar (300 psi)

Temperature: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Increased durability from robust rotating spring compression unit that helps to keep solids away from the seal faces and removes seal-generated heat

- Improved reliability with rotating seal ring that is independently centered on the shaft and has multiple springs and drive pins that evenly distribute the load

- Broad application flexibility enabled by completely interchangeable shaft packing materials, dimensionally interchangeable insert mounting, and compression unit availability in any machinable metallurgy

The CRO is an economical, single-coil spring, friction drive component seal for use in pumps with packing box seal chambers. Available in single or dual arrangements.

specifications

Press. to: 20.7 bar (300 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Longer service life derived from rotating seal ring that self-centers around the shaft and withstands the harsh demands of cyclic operation or continuous duty

- Increased durability from robust single-coil spring that resists clogging and chemical attack

- Simplified installation and improved corrosion resistance due to a design with a minimum number of seal components with heavy cross-sections

With its composite rotor, the RA single outside-mounted component seal is a cost-effective solution for highly corrosive chemical services. Suitable for metallic and nonmetallic equipment, such as plastic, glass and lined designs.

specifications

Press. to: 27.6 bar (400 psi)

Temp: -40°C to 177°C (-40°F to 350°F)

Speeds to: 23 m/s (75 fps)

Sizes: 13 to 127 mm (0.500 to 5.000 in)

FEATURES & BENEFITS

- Installation ease with design that attaches to the outside of the seal chamber

- Corrosive application performance and flexibility provided by seal faces and elastomers in diverse materials, plus non-wetted drive collar, springs and drive pins on the RA-C configuration to avoid the need for expensive alloys

- Greater reliability assured by flexible rotor design, hydraulically balanced to provide proper face loading

- Better process control via double O-ring mounted stator that prevents distortion

BX Series balanced rotating metal bellows seals provide exceptional reliability in corrosive and non-corrosive fluids, especially those that crystallize. Fully compliant with API 682 Type B, Arrangements 1, 2 and 3.

specifications

Pressure: to: 27.6 bar (400 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 12.3 to 127 mm (0.483 to 5.000 in)

FEATURES & BENEFITS

- Longer service life with 0.20 mm (0.008 in) thick standard welded metal bellows for resistance to corrosion, shaft vibration and centrifugal forces

- Optimal performance ensured by three standard seal face balances; the BXQ seal is high balanced for flashing hydrocarbon applications

- Increased maintenance intervals due to self-cleaning rotating bellows that replace springs and dynamic elastomers

- Performance benefits of metal bellows in dual pressurized Arrangement 3 seals with the BXB seal’s unique ID pressurized seal face balance

Built for temperatures beyond the limits of elastomers, the BXRH balanced stationary metal bellows seal offers reliable sealing at high speeds. Meets all API 682 Type C requirements in Arrangements 1, 2 and 3.

specifications

Press. to: 20.7 bar (300 psi)

Temp: -73°C to 427°C (-100°F to 800°F)

Speeds to: 46 m/s (150 fps)

Sizes: 21.8 to 127 mm (0.857 in to 5.000 in)

FEATURES & BENEFITS

- Optimal performance resulting from flexible graphite gasketing in lieu of elastomers to improve temperature and chemical compatibility

- Reliability due to extra-long Alloy 718 bellows that offer superior corrosion resistance, allow more axial travel, and provide consistent spring loading

- Application flexibility arising from single and dual seal configurations as well as pressurized and unpressurized arrangements

- Reduced clogging due to absence of springs and dynamic elastomers, plus standard anti-coke device

This dual pressurized non-contacting, gas barrier pusher seal is used in applications where zero emissions of hazardous pumped products can be tolerated.

SPECIFICATIONS

Press. to: 34.5 bar (500 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds: 1.3 to 25 m/s (4 to 82 fps)

Sizes: 25.4 to 152 mm (1.000 to 6.000 in)

FEATURES & BENEFITS

- Environmental regulatory compliance assured by inert gas barrier that operates with zero process emissions

- Greater reliability enabled by spring energized O-ring technology to maintain proper seal face tracking

- Longer service life from silicon carbide seal faces using APG precision face topography, which creates a stiff, thin gas film that prevents wear

- Economical performance via non-contacting seal faces that require very low power consumption during startup and operation

GX-200 dual metal bellows seals utilize APG non-contacting seal face technology for outstanding performance in a variety of applications. Fits standard or small bore seal chambers without modifications.

SPECIFICATIONS

Press. to: 13.8 bar (200 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds: 2.5 to 35 m/s (8 to 115 fps)

Sizes: 25.4 to 76.2 mm (1.000 to 3.000 in)

FEATURES & BENEFITS

- Environmental regulatory compliance assured by inert gas barrier that operates with zero process emissions

- Long-term reliability provided by high alloy metal bellows that resist contamination and hang-up while providing pressure reversal product containment during upset events

- Lower operation and maintenance costs provided by unique design that eliminates the costs of maintaining a liquid barrier system and the risks of barrier fluid contamination

- Economical performance enabled by energy-efficient design that delivers the industry’s lowest power consumption for conventional pumps

The BRO Seal was designed for large diameter mixer shafts. The unique design allows a large cross-section of carbon to be used as a seal ring, so that the rotating carbon face can be assembled in the rotary unit by the seal manufacturer.

SPECIFICATIONS

Press. up to 400 psig (27 bar)

Temp: up to 250 F (121 C)

Speeds to: 3500 fpm (18m/s)

FEATURES & BENEFITS

- Flowserve designed the BRO seal to handle shaft movement found in larger shaft sized equipment.

- Maximum flexibility of the rotating seal is achieved because the carbon seal ring can float within the shroud.

- Balanced version is called BPO

- Seal is designed to fit most OEM housings.

M Series vertical shaft mixer seals easily adapt to changing production requirements. They are designed for use with mixers, agitators, filters and dryers as well as steel- or glass-lined vessels.

specifications

Press: vacuum to 35 bar (500 psi)

Temp: to 200°C (390°F)

Speed: to 10 m/s (33 fps)

Sizes: 40 to 220 mm (1.575 to 9.000 in)

FEATURES & BENEFITS

- Unprecedented application flexibility provided by cartridge canister design that enables the seal faces to be changed out to run wet (MW), dry contacting (MD) or dry non-contacting gas barrier technology (ML)

- True component standardization with reduced inventory carrying costs owing to a high degree of parts interchangeability across the product line

- Optional materials compliant with FDA CFR 21, USP Class VI, ADI Free Components and similar specifications

- Specialized solutions customized up to 480 mm (18.900 in) shaft size (MWC-200)

SLC seals are heavy-duty, single pusher cartridge seals built for the harshest slurry pump services found in mining, mineral and ore processing, and flue gas desulfurization. Suitable for solids to 60% by weight.

sPECIFICATIONS

Pressure: to: 20.6 bar (300 psi)

Temperature: -18°C to 110°C (10°F to 230°F)

Speeds to: 15 m/s (50 fps)

Shaft Sizes: 32 to 220 mm (1.250 to 8.661 in)

FEATURES & BENEFITS

- Lower operating costs ensured by unique non-clogging, encapsulated cone spring, which increases reliability and enables flushless operation

- Maximized equipment uptime provided by abrasion-resistant metal components and silicon carbide faces that extend seal life beyond that of slurry pump components

- Economical performance via clean, open design, which operates without flush water to reduce product dilution and eliminate flush water costs

- Ease of installation resulting from cartridge design that requires no special tools or bearing housing adjustments

The balanced single cartridge pusher seals has a flexible stator and operates without outside flush liquid to eliminate product dilution, increase plant efficiency and reduce costs.

SPECIFICATIONS

Pressure: to: 17.2 bar (250 psi)

Temperature: -40°C to 149°C (-40°F to 300°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 50 to 235 mm (2.000 to 9.250 in)

FEATURES & BENEFITS

- Increased reliability and consistent “no visible leakage” operation due to line-on-line, hydraulically balanced faces

- Extended seal life enabled by centroid-loaded monoblock rotor that helps to maintain zero net deflection, reducing leakage and wear

- Reduced maintenance costs provided by large cross-section stator O-ring, which allows maximum shaft movement while reducing the damaging effects of hang-up

- Dependable performance provided by single seals handling solids to 20%, dual seals to 60% solids, and quench options providing complete application flexibility

The RIS rubber-energized, component slurry seal features a unique non-clogging design that does not utilize springs or bellows. Handles solids to 50% by weight.

SPECIFICATIONS

Press. to: 10.3 bar (150 psi)

Temperature: -4°C to 110°C (25°F to 230°F)

Speeds to: 11 m/s (36 fps)

Shaft Sizes: 32 to 235 mm (1.250 to 9.250 in)

FEATURES & BENEFITS

- Ease of installation provided by innovative adaptive components that allow the seal to be installed from the wet end and adjusted externally

- Longer MTBF from non-clogging elastomer spring design that has no dynamic O-ring to hang up

- Reliable operation ensured by the rubber-energized stationary seal face that holds the seal faces together and absorbs relative shaft movement

- Reduced operating costs and improved control made possible by flushless operation, which is especially beneficial in flue gas desulphurization

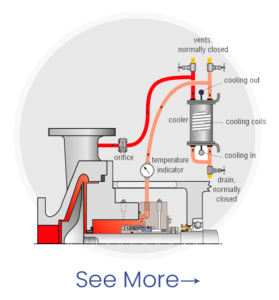

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements

The Seal Gard manages seal water flow rates for single and dual seals to improve the mean time between planned maintenance of your rotary equipment by improving the environment in the seal area.

specifications

Flows to: 13 lpm (3.5 gpm)

Press. to: 25 bar (363 psi)

Temp: 0°C to 100°C (32°F to 212°F)

FEATURES & BENEFITS

- Lower operating cost from dependable flow control that saves water costs by reducing seal water usage

- Ease of operation assured by clear-view acrylic flow meter with vertical flow tube that resists fouling and vibration-resistant pressure gauge

- Reduced downtime enabled by standard check valve that prevents backup of product into the seal water line in the event of pressure reversal

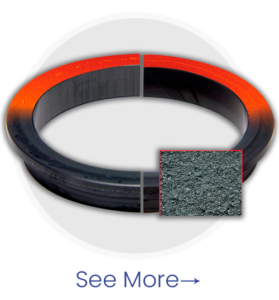

Tetracord is a universal joint sealant manufactured from 100% expanded PTFE and combined with a self-adhesive strip for easy application. It forms a quick, but permanent seal on anything from a pipe joint to a manhole cover.

specifications

Pressure up to 3000 psi

Temp up to 600 F

pH Range: (all fluids except free fluorine and molten alkali metals)

FEATURES & BENEFITS

- Adhesive backing for easy installation, is soft and flexible so it handles curves and contours.

- It is sold in continuous cord form so you only cut off what you need each time.

- Installation takes only minutes, and removal of the sealant is simple and involves no scraping, which saves downtime and money.

- Strong, durable PTFE material has excellent chemical resistance to many acids, alkalis, salts and organic chemicals.

- It is also asbestos-free, non-toxic and noncontaminating, so it is a good sealant choice for food, pharmaceuticals, and diagnostics applications.

- Tetracord is also recommended for heavy duty applications such as high pressure steam turbine housings and fragile glass joints.