Water Resources

Water Resources

Water Resources

Water Resources

Whether for flood control, desalination, distribution, waste management or agriculture, those who move water need to do it economically, sustainably and reliably. They need low-maintenance equipment and high-efficiency systems that minimize energy consumption. They also need partners who ensure the right solution is specified every time to minimize environmental impacts and control total lifecycle costs. Supplying flow management systems for global water resources is a commitment with far-reaching implications. That’s why the world’s leading municipalities and water system providers trust Flowserve.

Water Resources

Whether for flood control, desalination, distribution, waste management or agriculture, those who move water need to do it economically, sustainably and reliably. They need low-maintenance equipment and high-efficiency systems that minimize energy consumption. They also need partners who ensure the right solution is specified every time to minimize environmental impacts and control total lifecycle costs. Supplying flow management systems for global water resources is a commitment with far-reaching implications. That’s why the world’s leading municipalities and water system providers trust Flowserve.

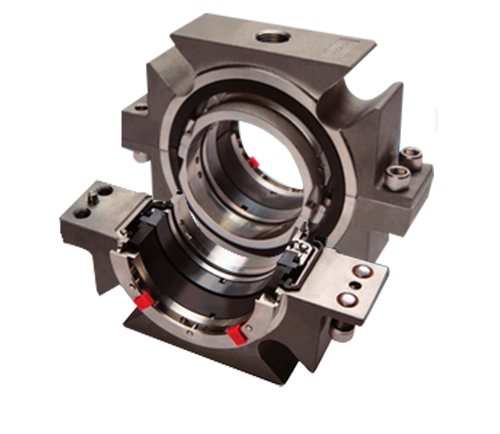

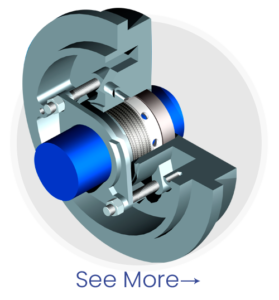

The PSS 4 semi-cartridge split seal is ideal for pump and mixer applications. With only two major components, it makes installation quick and easy without requiring equipment teardown.

SPECIFICATIONS

Press.: Vacuum to 30 bar (450 psi)

Temp: -18°C to 121°C (0°F to 250°F)

Speeds: to 19.3 m/s (3800 fpm)

Sizes: 38 to 152 mm (1.500 to 6.000 in); contact Flowserve for larger sizes

FEATURES & BENEFITS

- Exclusive 3D Key technology assures optimum face alignment in both axial and radial direction, reducing leakage and installation time

- Unique setting tabs eliminate all seal positioning, measuring and marking, assuring installation success

- Easily handles mixer equipment runout up to 1.5 mm (0.060 in) TIR radial shaft movement

- Fully split design installs easily around the shaft, outside the seal chamber, eliminating the need to dismantle the equipment

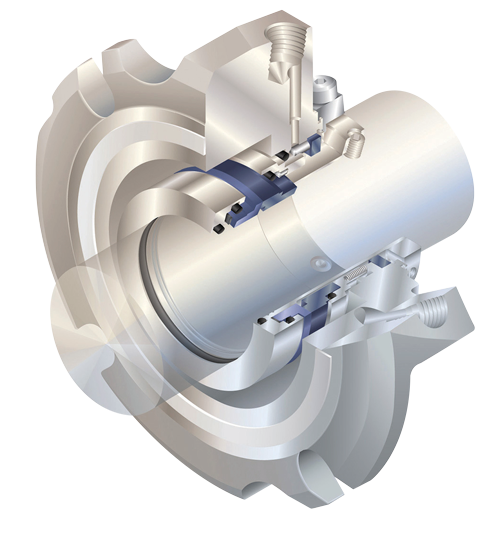

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

specifications

Pressure: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: pusher 25 to 200 mm (1.000 to 8.000 in); bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

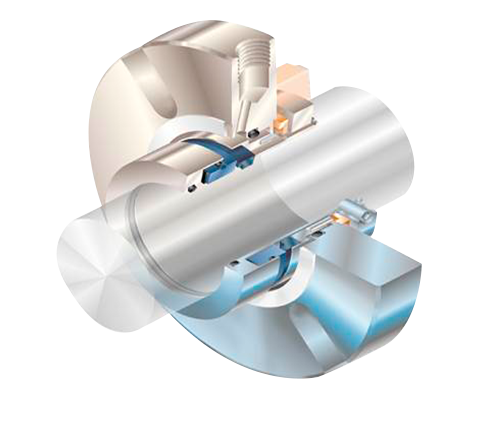

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

specifications

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

The Series 80 seal is one of Flowserve’s Heritage products that has a proven track record of performance. Built with premium materials, this Stationary designed, Hydraulically balanced seal succeeds in the most challenging applications.

Flowserve spun off the more popular sizes of the Series 80 and formed the CPM seal which allows us to compete with today’s low cost seal manufacturers. The CPM line of seals are used for competitor change outs in general service applications. Compared to other light duty seals, the CPM seal weights 30% more due to the heavy duty gland design. The flush port is also larger than most light duty seals making the CPM seal a better all-around choice.

SPECIFICATIONS

Press. to vacuum to 400 psig (27 bar)

Temp: -40 to 400 F (-40 to 204 C)

Speeds to: 100 ft/min (30m/s)

Sizes: 3/4″ to 3.750″

FEATURES & BENEFITS

- Robust rotary face design is flexibly mounted, enhancing the ability to survive shock and face distortion typically found in clamped seal face designs.

- Springs located outside the process fluid deter chemical stress corrosion and spring clogging by dirty process fluids.

- Hydraulically balanced seal design reduces friction, heat and wear with lower loading forces while maintaining a lubrication film between the mating faces.

- Floating stationary to accommodate out-of-square pump misalignment.

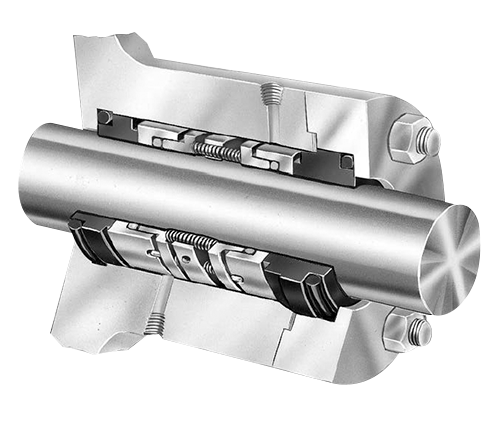

This single, unbalanced, multi-spring component seal is usable as an inside or outside mounted seal. Suitable for abrasive, corrosive and viscous fluids in chemical services.

specifications

Pressure: to: 20.7 bar (300 psi)

Temperature: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Increased durability from robust rotating spring compression unit that helps to keep solids away from the seal faces and removes seal-generated heat

- Improved reliability with rotating seal ring that is independently centered on the shaft and has multiple springs and drive pins that evenly distribute the load

- Broad application flexibility enabled by completely interchangeable shaft packing materials, dimensionally interchangeable insert mounting, and compression unit availability in any machinable metallurgy

The CRO is an economical, single-coil spring, friction drive component seal for use in pumps with packing box seal chambers. Available in single or dual arrangements.

specifications

Press. to: 20.7 bar (300 psi)

Temp: -40°C to 260°C (-40°F to 500°F)

Speeds to: 23 m/s (75 fps)

Sizes: 9.5 to 115 mm (0.375 to 4.500 in)

FEATURES & BENEFITS

- Longer service life derived from rotating seal ring that self-centers around the shaft and withstands the harsh demands of cyclic operation or continuous duty

- Increased durability from robust single-coil spring that resists clogging and chemical attack

- Simplified installation and improved corrosion resistance due to a design with a minimum number of seal components with heavy cross-sections

Construction: Multi-Lok Braid

SPECIFICATIONS

Shaft speeds to 1885 FPM

Temperatures to 450°F/232°C

pH range 4-10

FEATURES & BENEFITS

- Non-asbestos fibers treated with a specially formulated blend of lubricants having a saxoline base.

- Each strand is individually coated with graphite and the braid is surface coated with graphite.

- General service on rotary and reciprocating equipment.

- Recommended For: Mild acids, alkalies, steam, brine, oil.

- Good general service packing. The lubrication formulation makes the extra difference. The ductile nature of the lubricant prevents wicking and provides superior sealability.

- Style 402 – Same as ML402 except square braided.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 3600 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

- PTFE/Graphite composite yarn for wide ranging plant applications including aggressive fluids and high temperatures.

- Equipment: Pumps, agitators and mixers

- Recommended For: All corrosive applications suitable for PTFE and graphite.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 4400 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

- Finely ground particles of the highest quality graphite in a PTFE matrix to control graphite migration. 100% GFO® Yarn.

- Equipment: All reciprocating and rotating shafts.

- Recommended For: All corrosive applications suitable for PTFE and graphite.

GFO® is a registered trademark of W.L. Gore and Associates

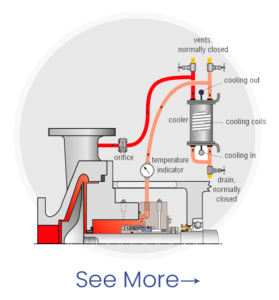

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements

The Seal Gard manages seal water flow rates for single and dual seals to improve the mean time between planned maintenance of your rotary equipment by improving the environment in the seal area.

specifications

Flows to: 13 lpm (3.5 gpm)

Press. to: 25 bar (363 psi)

Temp: 0°C to 100°C (32°F to 212°F)

FEATURES & BENEFITS

- Lower operating cost from dependable flow control that saves water costs by reducing seal water usage

- Ease of operation assured by clear-view acrylic flow meter with vertical flow tube that resists fouling and vibration-resistant pressure gauge

- Reduced downtime enabled by standard check valve that prevents backup of product into the seal water line in the event of pressure reversal