Vibration Equipment Monitoring System

Through the application of advanced technologies, the Flowserve Intelligent Process Solutions (IPS) Family of products helps customers proactively manage their plant assets to increase plant uptime and reduce equipment life cycle costs. Flowserve offers advanced monitoring solutions- wired and wireless – for permanent and portable data collection and analysis of vital assets. Monitoring and control solutions from Flowserve are engineered specifically to address process and equipment issues. As a result, user interfaces are highly intuitive and information is easy to interpret and immediately actionable. In addition, Flowserve is on the leading edge of predictive monitoring and diagnostics. Onboard sensors and intelligent algorithms make it possible for plant operators to predict system behavior before failure or disruption, thus protecting their most critical plant assets.

IPS Solutions

Moving from reactive to predictive

- Transitions reliability practices from reactive to predictive to improve reliability and reduce overall maintenance costs

Solutions that are practical and economical

- Systems that capture data and generate actionable information are easy to use and ready now

Systems that are scalable

- Plant- or enterprise-wide solutions that integrate with broader operational technology strategies

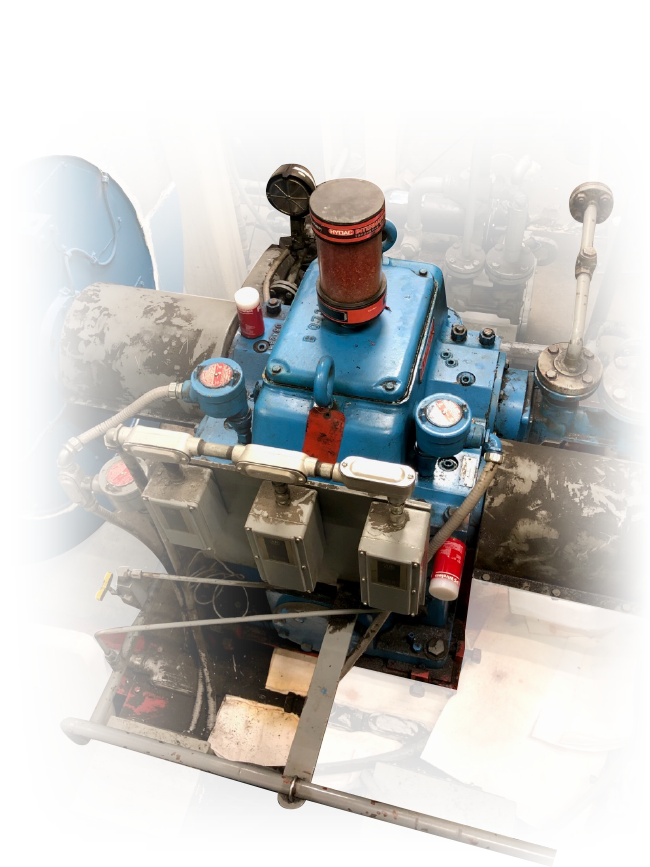

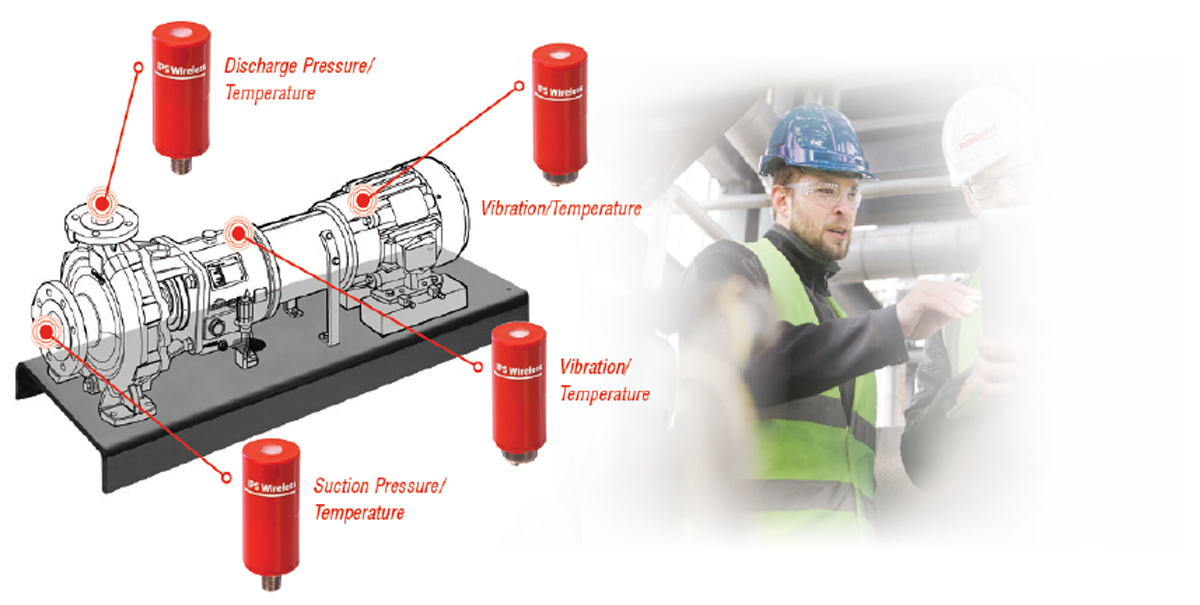

IPS Node … Pressure, Temperature, Vibration

The goal of predictive maintenance is to quickly identify equipment failures before they occur. The Flowserve IPS Node is a cost efficient monitoring device that continuously reports critical equipment performance information:

- Wireless data transmission of sensor information: pressure, temperature, vibration (including FFT 8 Peak Data), discrete and 4-20mA signal

- Ability to set alarm thresholds for sensor signals so that authorized personnel can be notified. Reports are generated daily to show the health of the equipment at a glance.

Improving reliability & efficiency … while lowering cost

IPS Node Features

Wirelessly monitors temperature, vibration (x-y-z), pressure, discrete, 4-20 mA on rotating equipment systems

Checks, at a user assigned interval, for outside expected threshold operation and indicates status via daily report, email, or text message.

- Pre set parameters are established from data published by the vibration institute per the type of equipment being monitored

Suitable for Class I, DIV 1, Zone 0 environment, IP-66 with a battery life 3-4 years

Omni directional 3D radial field long range wireless communications

Processes Sensor Signals Internally

Wirelessly transmits data back to IPS Receiver via Smart Repeater System

Sensor signals interfaced to desired system (DCS, CMMS, or Flowserve hosted IPS Insight) via the IPS Receiver / Interface System

Direct tap / Spot face

Epoxy mount on 316 stainless steel pad

Magnetic mount

More powerful,

reliable wireless edge device …

in a compact, intrinsically safe,

and cost-effective design

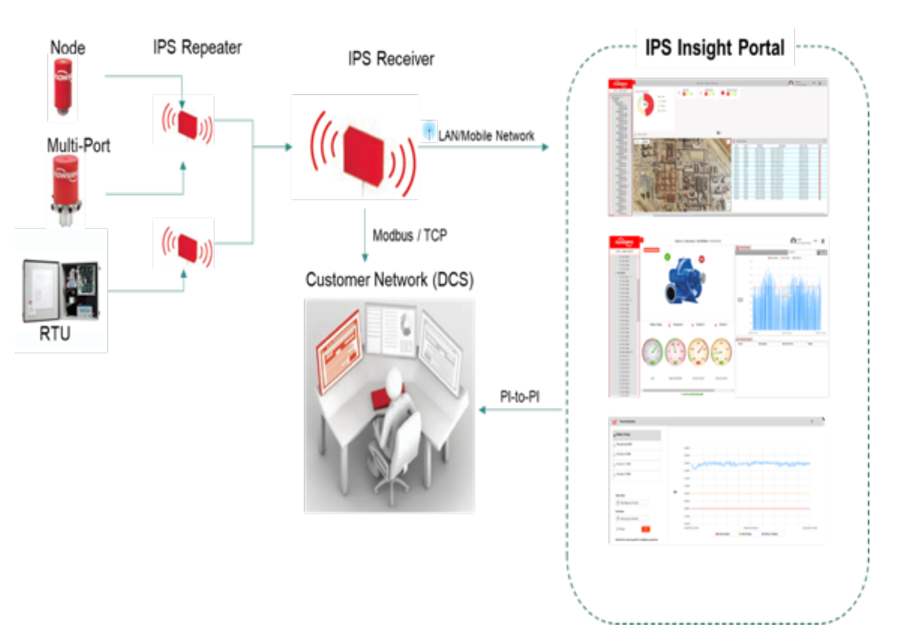

IPS Products and Technologies

Understanding the flow of data and information

IPS Wireless — Other Key Components

WIRELESS INFRASTRUCTURE FOR

RANGE AND CONNECTIVITY

REPEATER

- Receives signal from IPS transmitters, amplifies, and sends to receiver

- AC or solar powered

- Class I, DIV 2, ATEX Zone 2

RECEIVER

- Serves as central collection point for data

- Collects up to 2500 IPS transmitter signals

- Sends data to the online IPS Insight™ portal

- Can be locally integrated with DCS/PI/MMS/SCADA/Data Historian using Modbus RTU protocol (over RS232, RS485 or TCP/IP)

- AC powered

IPS Repeater

- Receives signal from IPS Transmitters,

- Amplifies, and sends to receiver

- Allows for unlimited range of IPS Transmitters.

- Power options available 110vac / 24vdc

- Solar power with 30 day battery back up

- Average of 6 hours per day sunlight for full charge

- Yearly PM required

- Class 1, Div. 2 area ratings

- CSA, Ex ia, Atex and IECEX

- NEMA 4X Enclosure

- Strategically installed at elevated locations

- Status check in with IPS Receiver

Solar Powered Repeater with easy deployment for either pole or beam mount

IPS Receiver

Two box receiver system

Inside panel upper right and outside panel bottom

Serves as central collection point for data

Collects up to 3000 IPS Transmitter signals

Class 1, Div. 2 area ratings

CSA, Ex ia, Atex and IECEX

Powered by 110vac or 24vdc

NEMA 4X enclosure

CSA, Ex ia, Atex and IECEX

Dedicated Ethernet connection preferred

Options for cellular or satellite

Options to view data in DCS/PIE/MMS through serial/Modbus