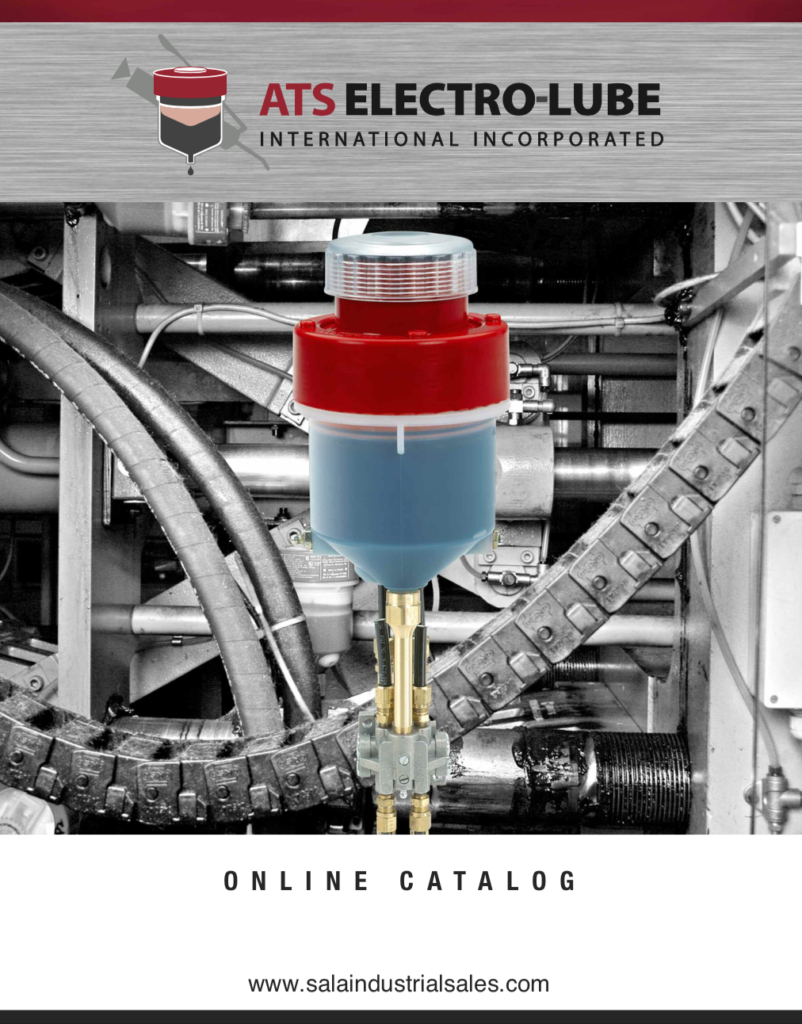

Ultimate Luber (Refillable Unit)

Developed to be more powerful than the original Electro-Luber, The ULTIMATE LUBER™ is a motor-driven automatic lubricator which is refillable using standard grease guns. It’s microprocessor-controlled, energy-efficient motor delivers grease to a fixed-displacement pump that produces pressures over 1000psi! This strength allows the ULTIMATE LUBER™ to perform multi-point lubrication and drive lubricant through long feed lines to progressive distributors. When a dispensing cycle is selected, the units will activate at programmed intervals. At each interval, the ULTIMATE LUBER™ dispenses approximately 1.25cc of grease. Neither temperature nor altitude will affect the lubricant output.

Using our powerful MD unit and a distribution blocks, cutting costs has never been easier: a single unit can act as a mini central-lube system feeding up to 12 different points. Remote mount your unit outside of the hazardous and hard to reach areas to reduce risk to employees. Our ULTIMATE units make machinery maintenance easier, cheaper and safer!

- Over 1000 psi

- -20ºC to +55ºC operating temperature

- Remote mounting to 10m

- One unit services up to 12 lubrication points

- Single or Multi-point lubrication

- Refillable on site & lasts many uses

- Available in 60, 125, 250 or 500cc

- Remote control& AC/DC power available

Features & Specifications

- Most powerful automatic lubrication system on the market. Produces over 1000psi, which enables it to service single-point applications up to 30′ away (9 m) and multi-point applications up to 20′ (6 m) away

- UL/CUL Div. 2 Hazardous Area approved

- Available in 4 sizes: 2, 4, 8, or 17 oz. (60, 125, 250, or 500cc)

- Single-or Multi-Point configuration

- Refillable using a standard grease gun (no other tools needed)

- Able to service up to 12 lube points with optional progressive distribution block

- Available with replaceable battery packs or optional external power sources (AC and DC)

- Optional Remote Control available to connect to customer machinery or control equipment (e.g. PLC, Contactors, Relays)

- Suitable for indoor-outdoor use

- Optional easy to install mounting brackets and mounting platesfor either single-or multi-point applications are available.

- Multiple settings to empty from 15 days to 2 years

- Operating range from -4F to 131F (-20 C to +55). NOTE:Low-Temp lubricants must be used at low temperatures

- The Ultimate has an internal blender to minimize grease separation and enhance lube consistency

Benefits

- Consistently lubricates at intervals of your choice

- Works in hazardous or hard to reach areas

- Can be remote mounted for safety and convenience

- Extends equipment life

- Prevents grease contamination

- Reduces maintenance costs

- Eliminates downtime for costly repairs

- Simple installation and refilling

- Massively reduces costs by a single unit feeding up to 12 points

- The most powerful unit on the market!

Jack Luber (Replacement Grease Cartridge)

- The JACK LUBER™ is the most versatile automatic lubrication system in the ATS product line. We took all of the most popular features from each of our luber series and incorporated them into one unit. We took the cold-temp ability from our ELECTRO-LUBER™ Series, the raw power of the motor from the ULTIMATE™ Series, the convenient replaceable cartridge idea from our TITAN™ Series but added in a few bonuses on the way: our JACK Luber comes with a unique JACKSCREW mechanism to ensure that our JACK works in seriously cold temperatures plus, we made it our most affordable motor-driven unit yet! This mid-price range lubricator is truly the “Jack” of all trades.

- The JACK LUBER utilizes a replaceable, one-time use cartridge that changes out in seconds. The drive unit for the JACK LUBER is pure ULTIMATE power and runs off the ATS battery pack or with an optional AC/DC adaptor. Producing over 200 psi, the JACK LUBER is capable of heavy duty applications running long lines up to 6m (approx. 20 ft). This lubrication system is tough, reliable, and easy to manage. The JACK LUBER saves time, money and gives you the performance you need!

Up to 200 psi

Replaceable grease cartridge

Lasts multiple uses

Remote mounting to 20’ (6m)

Maintenance free for up to 1 year

Available in 125cc and 250cc

4°F to +140°F (-20ºC to +60ºC) operating temperature

Remote control & power options available

Size & Dimensions

Jack Luber Model 125: 7-1/2” high X 3-1/8” dia.

Jack Luber Model 250: 11-1/2`` high X 3-1/8`` dia

Features & Specifications

Self-Contained, stand-alone automatic, single point lubricator

Pressures over 200 psi.

Available in 2 sizes: 125cc and 250cc

Available with long-life replaceable battery packs (provided with original purchase and replacement cartridge), or optional external power sources.(AC and DC)

Optional Remote Control available to connect to customer machinery or control equipment (ex. PLC, Contactors, Relays)

1/2” NPT male grease output.

UL/CUL Div. 2 Hazardous Area approved

Multiple settings to empty from 15 days to one year.

Suitable for indoor/outdoor use

May be remote mounted to 6m (approx. 20 ft) using 1/4” ID hose.

Replaceable, single use cartridge filled with customer-specified lubricant.

Operating range from -4°F to +140°F (-20°C to +60°C)

Benefits

Maintenance-free lubrication for up to 1 year

Virtually ANY lubricant can be used

Economical unit -reuse the motor and only replace the grease cartridge and batteries

Low price-point; nearly the same cost as most single-point lubricators

Reduces workplace accidents by safely working in dangerous or hard to reach areas

Can be remote mounted up to 6m for safety and convenience

Extends equipment life by reliably lubricating

Can withstand extreme high heat (up to 60°C/+140°F)

Eliminates downtime for costly repairs

Simple installation without tools

- The classic ELECTRO-LUBER series was developed in 1982. The ELECTRO-LUBER is a single point automatic lubricator that uses an electro-chemical reactor cell which converts electrical energy into safe, inert nitrogen gas. The gas is contained in a hermetically sealed bellow-type gas chamber. ATS Electro-Lube was the first company to use this self-contained auto luber technology and sets the industry standard. As the gas is produced, internal pressure builds up in the bellows and is applied against the orange piston. The piston then forces the lubricant out of the cylinder and into the point of lubrication. The unit can empty from between 15 days to one year, depending on the setting of the simple user-programmable DIP switch. This selection can be changed or turned off at any time.

Electro-Luber

(Disposable Unit)

- The Electro-Luber series can be filled with any lubricant and used in virtually every work environment. Our lubers are intrinsically safe and approved for all explosive areas. They are also certified by MSHA for use in mines. They can be filled with food-safe lubricant and will work underwater up to 30′ (10m) deep!

- Our units are simple to use, effective and drastically reduce the risk of bearing failure by ensuring that your machines are continuously lubricated with the right amount of lubricant at the correct time. ATS’ Electro-Lubers have been saving clients time and money for over 3 decades!

Maximum 50 psi

-40C to +55C operating temperature

Waterproof to 10m

Remote mounting & remote control options

ATEX/UL certified (all explosive zones)

Use with ANY lubricant

Available in 60, 125, 250 or 475cc

Recall rate less than 0.001%

Size & Dimensions

Jumbo-Luber: 6-3/4″ high X 4-3/4″ dia.

Budget-Luber: 6-1/8″ high X 4″ dia.

Mini-Luber: 5-5/8″ high X 3-1/8″ dia.

Micro-Luber: 4-7/8″ high X 3-1/8″ dia.

Benefits

- Consistently precisely controlled lubrication

- Virtually ANY lubricant can be used

- Safe for use in all conditions, including food-safe and all hazardous areas.

- Intrinsically safe, ATEX/UL certified

- Dispensing of lubricant is not affected by ambient temperature or fluctuations (within lubricant and luber parameters)

- Reduces workplace accidents by safely working in dangerous or hard to reach areas

- Can be remote mounted for safety and convenience

- Extends equipment life by reliably lubricating

- Prevents lubricant contamination

- Reduces maintenance costs

- Eliminates downtime for costly repairs

- Simple installation without tools

Features & Specifications

- Self-Contained, stand-alone, single-point auto-luber

- Continuous lubrication using safe, inert, nitrogen gas. Continuous lubrication of bearings prevents intrusion of foreign matter, slows oxidation, aids in dissipating heat and ensures a constant supply of fresh lubricant

- Available in 4 sizes: 2, 4, 8, or 16 oz. (60, 125, 250 or 475cc)

- Pressures up to 50psi

- Approved for all explosive environments. Certified Intrinsically Safe for Class 1, Groups A, B, C, D, E, F, and G. Also certified by MSHA and Energy, Mines Canada for use in mining. ATEX certified units also available.

- Multiple settings to empty from 15 days to 1 year

- Suitable for indoor/outdoor use

- May be remote mounted to 3′ (1m)

- Filled with any customer-specified lubricant

- Temperature Range: -40F to +132F (-40C to +55C).

NOTE: Low-temp lubricants must be used at low temperatures