SEPCO Packing

SEPCO

Sealing Equipment Products Company, Headquartered in Alabaster, Alabama is a manufacturer with a long standing tradition of providing the highest quality fluid sealing solutions available in the market place. SEPCO products are manufactured in the United States, and are used in a wide variety of problem solving applications worldwide. SEPCO’s product line includes: compression pump packing, die-formed and cut rings, lantern rings, gaskets, and gasketing material.

Construction: Multi-Lok Braid

SPECIFICATIONS

Shaft speeds to 1885 FPM

Temperatures to 450°F/232°C

pH range 4-10

FEATURES & BENEFITS

- Non-asbestos fibers treated with a specially formulated blend of lubricants having a saxoline base.

- Each strand is individually coated with graphite and the braid is surface coated with graphite.

- General service on rotary and reciprocating equipment.

- Recommended For: Mild acids, alkalies, steam, brine, oil.

- Good general service packing. The lubrication formulation makes the extra difference. The ductile nature of the lubricant prevents wicking and provides superior sealability.

Construction: Multi-Lok Braid

SPECIFICATIONS

Shaft speeds to 4000 FPM

temperatures to 650°F/345°C

pH range 0-14 except in strong oxidizers

FEATURES & BENEFITS

- High strength yarns with high thermal conductivity and lubricity.

- Equipment: General service on rotary and reciprocating equipment including high speed pumps and slurry service.

- Recommended For: Pumps and agitators in pulp and paper, mining and other process industries.

- ML560’s high thermal conductivity and lubricity allow it to operate without flush water in some applications.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 3600 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

- PTFE/Graphite composite yarn for wide ranging plant applications including aggressive fluids and high temperatures.

- Equipment: Pumps, agitators and mixers

- Recommended For: All corrosive applications suitable for PTFE and graphite.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 4400 FPM

Temperatures to 550°F/287°C

pH range 0-14

FEATURES & BENEFITS

Construction: Multi-Lok Braid

- Finely ground particles of the highest quality graphite in a PTFE matrix to control graphite migration. 100% GFO® Yarn.

- Equipment: All reciprocating and rotating shafts.

- Recommended For: All corrosive applications suitable for PTFE and graphite.

GFO® is a registered trademark of W.L. Gore and Associates

Construction: Multi-Lok Braid

specifications

Shaft speeds to 4000 FPM

temperatures to 850°F/454°C in oxidizing conditions

Temperatures to 1200°F/649°C in steam

pH range 0-14 except strong oxidizers.

FEATURES & BENEFITS

- Pure homogenous graphite bonded to a fiberglass carrier for strength and thermal stability.

- It has no added lubricants or binders to cook out or become brittle.

- Treatment: None.

- Equipment: Pumps and valves, volatile organic chemical service.

- Recommended For: Rotating shafts where high shaft speeds and thermal conductivity are required.

Construction: Multi-Lok Braid

specifications

Shaft speeds to 2500 FPM

temperatures to 500°F/260°C

pH range 3-11

FEATURES & BENEFITS

- A combination braid of PTFE/Graphite composite yarn and aramid fibers.

- This construction provides the strength of aramid fibers and the heat dissipating and lubricating qualities of the PTFE and graphite matrix.

- Treatment: Light coat of an inert break-in oil.

- Equipment: Paper mill stock pumps, agitators, or any service where strength and good lubricating qualities are needed.

SPECIFICATIONS

Shaft speeds to 1900 FPM

temperatures to 500°F/260 °C

pH range 3-11

FEATURES & BENEFITS

- Non-asbestos aramid fiber

- Multi-lock braid construction

- Each strand is individually treated with a PTFE coating and a light, inert oil

- Recommended for use in general service, caustics, mild acids, chemicals, air, oil gases, solvents, general chemical plant applications

- For use in rotating and reciprocating shafts; all equipment handling tough abrasive products

ML2400 is a Muli-Lok braided packing with SEPCO’s unique lubrication process that transforms each individual fiber into a reservoir of lubrication for longer packing life. An excellent high performance alternative to Teflon.

SPECIFICATIONS

pH Range: 1-13 (except concentrated or hot sulfuric or nitric acid).

Temperatures: 500°F / 260°C Max.

Speeds: 1800 fpm; 9.1 m/s

FEATURES & BENEFITS

- Proprietary non-petroleum lubricant containing no sulphur, silicon, or wax.

- Rotating and reciprocation pumps, washer journals, liquor pumps, refiners, digesters and many other uses.

- Recommended to use in general service applications where graphite may not be acceptable: steam, water, acid, chemical and solvent applications, multi-use in chemical plants and pulp and paper mills.

- A Full Line Manufacturer: Compression Packing for Pumps & Valves, Mechanical Seals, Flexible Graphite, Braided Fiberglass, Gaskets & Sheet Products, Packing Accessories

A proprietary blend of non-asbestos TEK-PRO yarns treated with PTFE throughout the packing. The PTFE suspensoid thoroughly seals and fills all voids providing better resistance to chemical attack. A light lubricant is applied under pressure to improve run-in properties.

specifications

Shaft speeds to 1885 FPM

temperatures to 550°F/288°C

pH range 3-12

FEATURES & BENEFITS

- Multi-lock braid construction

- The TEK-PRO yarns retain a greater volume of PTFE dispersion and are more uniformly distributed to provide longer and better sealing

- Recommended for pulp and paper mill applications, recovery pumps, chemical applications, caustic soda; an excellent all-around general service chemical packing

- For use in rotating and reciprocating pump and valve equipment, mixers and agitators

Yarns are dipped in PTFE suspensoid ensuring even distribution of the PTFE. The fibers are saturated and sealed with the PTFE particles, protecting the fibers from chemical action. The PTFE provides the packing with a greater degree of chemical inertness, lower coefficient of friction and prevents penetration of chemical fluids. The corner tracks are made from an Aramid filament yarn to reduce extrusion and increase pressure and strength characteristics.

SPECIFICATIONS

Shaft speeds to 1885 FPM

Temperatures to 500°F/260°C

pH 3-11

FEATURES & BENEFITS

- Multi-Lok Braid construction

- Recommended for: Caustics, mild acids, difficult chemicals, air, gases, solvents, oils, general plant applications

- For use in: General service, rotating and reciprocating pumps, and agitators

- A surface coating of PTFE is applied after braiding

- To assure good break-in characteristics, a special high temperature synthetic lubricant is added

specifications

Shaft speeds to 1200 FPM

temperatures to 500°F/260°C

pH range 0-14

FEATURES & BENEFITS

- Multi-lock braid construction

- Pure PTFE filament lubricated with a proprietary lubricant that complies FDA requirements

- For us on any equipment where braided packing is commonly used

- Recommended for use in the food processing industry or where an FDA material is required

Construction: Multi-Lok Braid

specifications

Shaft speeds to 4000 FPM

temperatures to 650°F/345°C in oxidizing atmospheres; 1200°F/650°C in steam

pH range 0-14 except in strong oxidizers

FEATURES & BENEFITS

- Construction: Multi-Lok Braid

- Car-Graf is a unique combination of amorphous carbon yarns treated throughout with fine particles of graphite

- Treated throughout with graphite

- For use in general service on rotary and reciprocating shafts, high temperature valves as end rings.

- Recommended for all chemical services in which carbon is suitable

specifications

Shaft speeds to 3000 FPM

temperatures to 600°F/345°C

pH range 0-14

FEATURES & BENEFITS

- ML 4461 Carlon is a carbon filament packing treated with PTFE to help prevent color contamination and carbon migration.

- Treatment: Each strand of the carbon yarn is treated and impregnated with a PTFE suspensoid, totally encapsulating the packing to prevent carbon filaments migrating into the system.

- Equipment: Pulp mill equipment, steaming vessels, top separators, refiners, outlet devices, blow pumps, stock pumps, agitators and valves.

- Recommended For: Most chemical services, except strong oxidizers.

specifications

Recommended for valve service

maximum line temperature 1200°F/649°C

pressure to 2500 p.s.i.

FEATURES & BENEFITS

- Braided Inconel wire-inserted carbon yarn over mastic core high temperature fibers and graphite

- A corrosion inhibitor is added to protect the valve

- Surface Treatment: Moly coated

- Recommended for steam, super heated steam, air petroleum products, hot gases

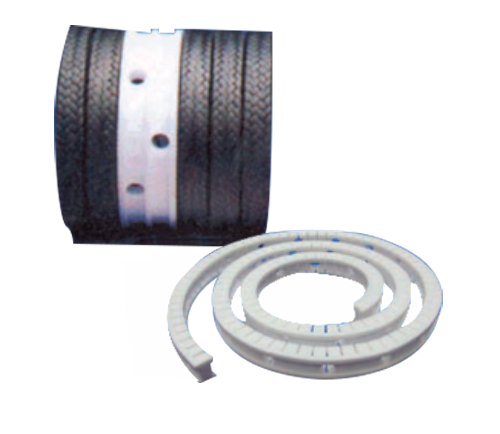

Sealing Equipment’s Hollow Core packings are specifically designed to seal large rotating equipment like mixers and agitators. Testing has proven that a high quality braided packing with a rubber core will outlast conventional pack

FEATURES & BENEFITS

- Styles: All packing styles are available in Hollow Core design.

- Sizes Available: 1/2” and up.

- Core Material: Silicone; standard (others upon request).

- Hollow Core: For rotating equipment.

- Solid Core: For static applications.

- Braid-Over-Braid: For severe run-out.

- Multi-Lok: For abrasive applications.

specifications

Temperatures to 550°F

pH range 0-14.

FEATURES & BENEFITS

- Made of 100% PTFE material, Flexible Lantern Material is an innovative approach to standard lantern rings, flexible lantern material is easier to install and remove.

- Sold in roll form like bulk packing, flexible lantern ring material can be cut to the specific length needed, therefore eliminating the need to stock many different size rings.

- Speeds up repacking because it is pliable enough to be removed easily

- Eliminates stock of many different materials because the PTFE material is designed for a wide variety of applications

Tetracord is a universal joint sealant manufactured from 100% expanded PTFE and combined with a self-adhesive strip for easy application. It forms a quick, but permanent seal on anything from a pipe joint to a manhole cover.

SPECIFICATIONS

Pressure up to 3000 psi

Temp up to 600 F

pH Range: (all fluids except free fluorine and molten alkali metals)

FEATURES & BENEFITS

- Adhesive backing for easy installation, is soft and flexible so it handles curves and contours.

- It is sold in continuous cord form so you only cut off what you need each time.

- Installation takes only minutes, and removal of the sealant is simple and involves no scraping, which saves downtime and money.

- Strong, durable PTFE material has excellent chemical resistance to many acids, alkalis, salts and organic chemicals.

- It is also asbestos-free, non-toxic and non-contaminating, so it is a good sealant choice for food, pharmaceuticals, and diagnostics applications.

- Tetracord is also recommended for heavy duty applications such as high pressure steam turbine housings and fragile glass joints.

The SEPCO® Pak-Lube™ is a waterbased lubricant designed to make installation of packing rings fast and easy. Many other packing installation lubricants are metal-based and can damage sleeves and shafts. Pak-Lube™ dissipates completely, leaving no harmful residue.

Style 500 is manufactured from 98% minimum pure graphite with a .002” thick 316 stainless steel insert that reduces gasket handling damage and increases pressure resistance. Style 500 has no binders or resins to cook out and will not cold flow. Recommended for high temperature and high pressure applications.

- Temperatures: In atmosphere: 932°F max; In steam: 1200°F max

- Pressures: 5000+ psi max

- pH: 0-14

- Sizes: 60” x 60”

- Thickness: 1/64”, 1/32”, 1/16”, 3/32”, 1/8”, 1/4”

SEAT-it is an installation tool that allows each ring of packing to be properly seated in the stuffing box resulting in:

- Increase Life of Packing

- Increase Packing Performance

- Decrease Energy Costs

- Easy installation