Pharmaceutical Industry

Pharmaceutical Industry

Pharmaceutical Industry

Pharmaceutical Industry

Our products and services emphasize precision, purity, and safety, adhering to the needs of pharmaceutical customers.

Pharmaceutical Industry

Our products and services emphasize precision, purity, and safety, adhering to the needs of pharmaceutical customers.

The VRA is an outside-mounted, dry-running single pusher seal designed to operate on top-entry agitators and mixers.

Self-lubricating carbon or filled PTFE seal faces run completely dry without cooling.

Cost savings provided by contacting dry-running design and two-piece collar, which respectively eliminate the need for a buffer fluid system and expensive alloys in non-wetted areas

SPECIFICATIONS

Press: vacuum to 13.8 bar (200 psi)

Temp: to 121°C (250°F)

Speed: to 350 rpm

Sizes: 25 to 178 mm (1.000 to 7.000 in)

FEATURES & BENEFITS

- Optimized for high run-out requirements — up to 3.81 mm (0.150 in) FIM

- High reliability provided by flexible rotor design that compensates for misalignment and double O-ring mounted stator that prevents distortion

- Reduced downtime facilitated by optional sanitary gland that allows steam cleaning and sterilizing of the seal’s interior while mounted on the equipment

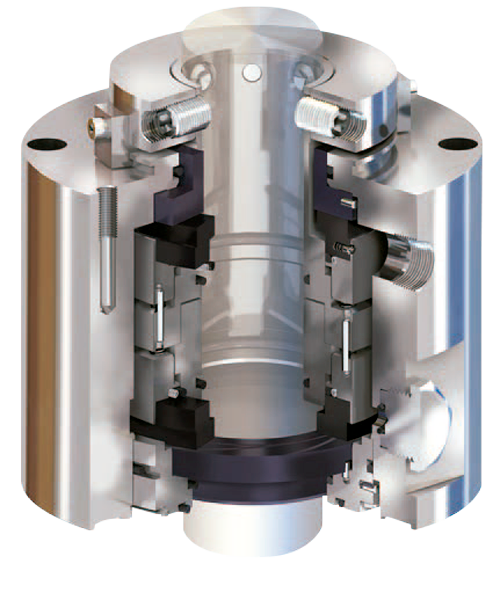

Top entry, dry contacting mixer seals

Equipment Type: Mixers, agitators, blowers, fans

SPECIFICATIONS

Pressure vacuum to 6.7 bar (100 psi)

Temperature -40 to 150°C (300°F)

Speed up to 1.5 m/s (5 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Dual pressurized gas barrier seal with contacting seal faces

- Product side seal has reverse pressure capability

- Dry-running for minimized product contamination from barrier fluid

- Features self-lubricating faces

- Cooling flange for higher temperatures up to 200°C (390°F) available

- Available with or without bearing

- Optional debris well at inboard seal

- Available for steel or glass lined vessels Other Configurations MD-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges MD-100

- Single dry running seal

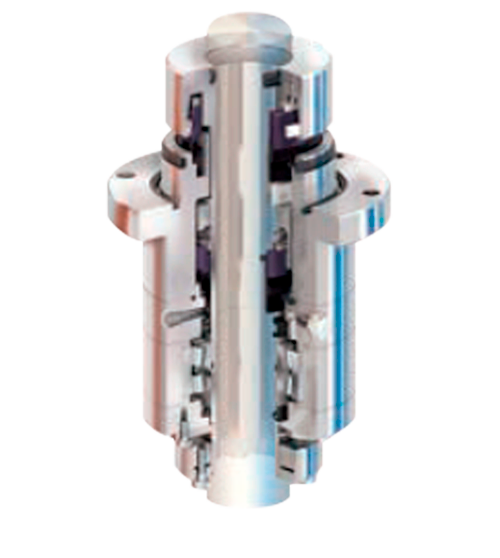

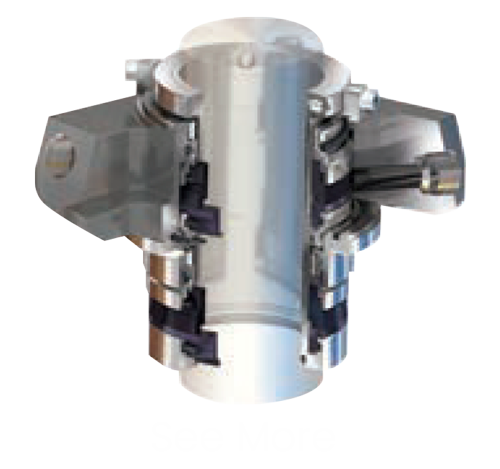

Top entry, wet mixer seals

Equipment Type: Mixers, agitators, filters, filter dryers

SPECIFICATIONS

Pressure vacuum to 35 bar (500 psi)

Temperature -40 to 200°C (390°F)

Speed up to 4 m/s (13 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Liquid lubricated seal

- Product side seal has reverse pressure capability

- Balanced dual pressurized seal

- Cooling coil options for higher temperatures available

- Cooling flange for higher temperatures up to 300°C (570°F) available

- Available with or without bearing

- Designed for steel or glass lined vessels Other Configurations MW-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges

- Available with or without bearing

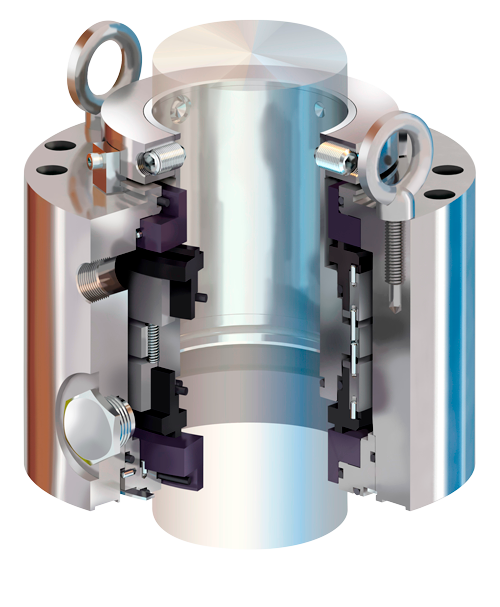

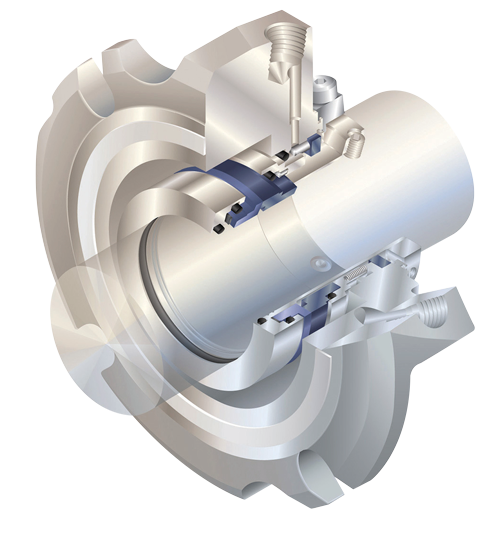

The Mixerpac family of mixer seals is designed for top-, side- and bottom-entry installations. Configurations available for slurry, sterile, high-pressure or large shaft movement applications.

Broad application flexibility owing to modular cartridge construction with and without bearing as well as liquid-lubricated and gas lift-off designs

SPECIFICATIONS

Press: vacuum to 250 bar (3600 psi)

Temp: to 200°C (390°F)

Speed: to 10 m/s (33 fps)

Sizes: 25 to 365 mm (1.000 to 14.400 in)

FEATURES & BENEFITS

- Extended seal life due to reduced friction and wear from balanced dual-pressurized design and seal faces optimized through FEA

- Reliable operation and improved safety with available reverse-pressure capability and emergency sealing solutions

- Numerous options, including cooling flange and sanitary gland/debris catcher, for applications requiring steam cleaning

- For more information on installation of this seal, please contact Carolina Seals, Inc.

Top entry, lift-off mixer seals

Equipment Type: Mixers, agitators, filters, filter dryers

SPECIFICATIONS

Pressure vacuum to 6.7 bar (100 psi)

Temperature -40 to 200°C (390°F)

Speed up to 10 m/s (33 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Noncontacting, lift-off gas barrier seal

- Advanced lift-off technology avoids wear from seal face contact

- Barrier leakage does not affect product quality

- Low drag design for the dynamic O-ring (no hang-up)

- Operates with a simple gas barrier support system

- Optional with or without bearing

- Cooling flange for higher temperatures up to 300°C (570°F) available

- Sanitary gland option for sterilization purposes

- Available for steel or glass lined vessels Other Configurations ML-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges

- Available with or without bearing

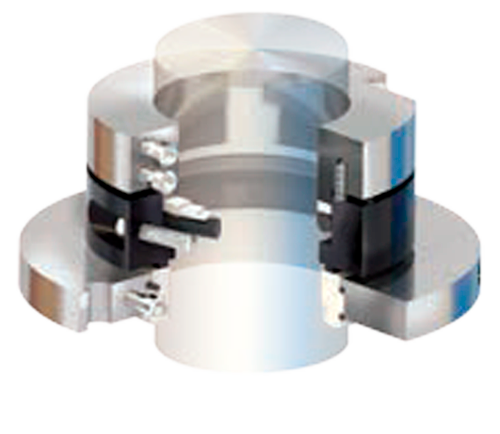

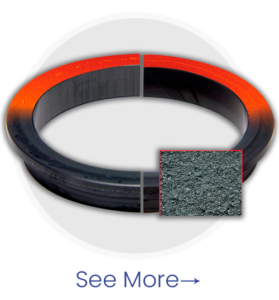

The MSS is for tough mixer and vessel applications where stuffing box face, bore and OD run-out are extreme. Typically used on older equipment or where compression packing had been used.

Easy installation, inspection and maintenance facilitated by outside seal arrangement and split design

SPECIFICATIONS

Press: vacuum to 7 bar (100 psi)

Temp: to 150°C (300°F)

Speed: to 1740 rpm

Sizes: 25 to 305 mm (1.000 to 12.000 in)

FEATURES & BENEFITS

- Fits in tight spaces with no equipment tear down; can be installed in cramped stuffing box areas where the bearing housing, gear box or coupling create obstructions

- Reliable operation owing to self-lubricating faces and design that dissipates heat from seal faces, which allows it to run dry or wet

- Product purity ensured by design that compensates for pressure reversals

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

SPECIFICATIONS

Press: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: pusher 25 to 200 mm (1.000 to 8.000 in);

bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

SPECIFICATIONS

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

The ISC2-MW is a dual-arrangement standard cartridge pusher seal engineered for reliable, cost-effective operation in mixer service.

SPECIFICATIONS

Press: to 6.9 bar (100 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speed: to 1.1 m/s (3.5 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reduced installation and maintenance costs assured by economical cartridge seal design for top-entry installation

- Increased uptime resulting from volute groove, which significantly increases barrier fluid flow to promote cool running, even at mixer speeds

- Reliable operation ensured by ISC2 thermal management technology that allows the seal to run cooler and tolerate dry-running events

- For more information on installation of this seal, please contact Carolina Seals, Inc.

The VRA is an outside-mounted, dry-running single pusher seal designed to operate on top-entry agitators and mixers.

Self-lubricating carbon or filled PTFE seal faces run completely dry without cooling.

Cost savings provided by contacting dry-running design and two-piece collar, which respectively eliminate the need for a buffer fluid system and expensive alloys in non-wetted areas

SPECIFICATIONS

Press: vacuum to 13.8 bar (200 psi)

Temp: to 121°C (250°F)

Speed: to 350 rpm

Sizes: 25 to 178 mm (1.000 to 7.000 in)

FEATURES & BENEFITS

- Optimized for high run-out requirements — up to 3.81 mm (0.150 in) FIM

- High reliability provided by flexible rotor design that compensates for misalignment and double O-ring mounted stator that prevents distortion

- Reduced downtime facilitated by optional sanitary gland that allows steam cleaning and sterilizing of the seal’s interior while mounted on the equipment

Top entry, dry contacting mixer seals

Equipment Type: Mixers, agitators, blowers, fans

SPECIFICATIONS

Pressure vacuum to 6.7 bar (100 psi)

Temperature -40 to 150°C (300°F)

Speed up to 1.5 m/s (5 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Dual pressurized gas barrier seal with contacting seal faces

- Product side seal has reverse pressure capability

- Dry-running for minimized product contamination from barrier fluid

- Features self-lubricating faces

- Cooling flange for higher temperatures up to 200°C (390°F) available

- Available with or without bearing

- Optional debris well at inboard seal

- Available for steel or glass lined vessels Other Configurations MD-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges MD-100

- Single dry running seal

Top entry, wet mixer seals

Equipment Type: Mixers, agitators, filters, filter dryers

SPECIFICATIONS

Pressure vacuum to 35 bar (500 psi)

Temperature -40 to 200°C (390°F)

Speed up to 4 m/s (13 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Liquid lubricated seal

- Product side seal has reverse pressure capability

- Balanced dual pressurized seal

- Cooling coil options for higher temperatures available

- Cooling flange for higher temperatures up to 300°C (570°F) available

- Available with or without bearing

- Designed for steel or glass lined vessels Other Configurations MW-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges

- Available with or without bearing

The Mixerpac family of mixer seals is designed for top-, side- and bottom-entry installations. Configurations available for slurry, sterile, high-pressure or large shaft movement applications.

Broad application flexibility owing to modular cartridge construction with and without bearing as well as liquid-lubricated and gas lift-off designs

SPECIFICATIONS

Press: vacuum to 250 bar (3600 psi)

Temp: to 200°C (390°F)

Speed: to 10 m/s (33 fps)

Sizes: 25 to 365 mm (1.000 to 14.400 in)

FEATURES & BENEFITS

- Extended seal life due to reduced friction and wear from balanced dual-pressurized design and seal faces optimized through FEA

- Reliable operation and improved safety with available reverse-pressure capability and emergency sealing solutions

- Numerous options, including cooling flange and sanitary gland/debris catcher, for applications requiring steam cleaning

- For more information on installation of this seal, please contact Carolina Seals, Inc.

Top entry, lift-off mixer seals

Equipment Type: Mixers, agitators, filters, filter dryers

SPECIFICATIONS

Pressure vacuum to 6.7 bar (100 psi)

Temperature -40 to 200°C (390°F)

Speed up to 10 m/s (33 fps)

Shaft Sizes 40 to 220 mm (1.575 to 9.000 inch)

FEATURES & BENEFITS

- Noncontacting, lift-off gas barrier seal

- Advanced lift-off technology avoids wear from seal face contact

- Barrier leakage does not affect product quality

- Low drag design for the dynamic O-ring (no hang-up)

- Operates with a simple gas barrier support system

- Optional with or without bearing

- Cooling flange for higher temperatures up to 300°C (570°F) available

- Sanitary gland option for sterilization purposes

- Available for steel or glass lined vessels Other Configurations ML-200 DIN

- Dimensions and flange connections to DIN for steel or glass lined flanges

- Available with or without bearing

The MSS is for tough mixer and vessel applications where stuffing box face, bore and OD run-out are extreme. Typically used on older equipment or where compression packing had been used.

Easy installation, inspection and maintenance facilitated by outside seal arrangement and split design

SPECIFICATIONS

Press: vacuum to 7 bar (100 psi)

Temp: to 150°C (300°F)

Speed: to 1740 rpm

Sizes: 25 to 305 mm (1.000 to 12.000 in)

FEATURES & BENEFITS

- Fits in tight spaces with no equipment tear down; can be installed in cramped stuffing box areas where the bearing housing, gear box or coupling create obstructions

- Reliable operation owing to self-lubricating faces and design that dissipates heat from seal faces, which allows it to run dry or wet

- Product purity ensured by design that compensates for pressure reversals

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

SPECIFICATIONS

Press: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: pusher 25 to 200 mm (1.000 to 8.000 in);

bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

SPECIFICATIONS

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

The ISC2-MW is a dual-arrangement standard cartridge pusher seal engineered for reliable, cost-effective operation in mixer service.

SPECIFICATIONS

Press: to 6.9 bar (100 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speed: to 1.1 m/s (3.5 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reduced installation and maintenance costs assured by economical cartridge seal design for top-entry installation

- Increased uptime resulting from volute groove, which significantly increases barrier fluid flow to promote cool running, even at mixer speeds

- Reliable operation ensured by ISC2 thermal management technology that allows the seal to run cooler and tolerate dry-running events

- For more information on installation of this seal, please contact Carolina Seals, Inc.

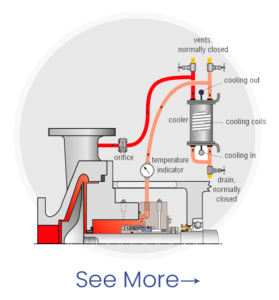

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements