Power Industry

Power Industry

Power Industry

Power Industry

Rapid load variations, frequent stops and starts, and the highest temperatures, flows and pressures. Welcome to fluid motion and control in the power industry. These grueling applications are where Flowserve became a driving force in power generation. To appreciate our role, you needn’t look further than our pioneering work in nuclear power or the massive machines we’ve built for conventional steam plants. But that’s history. Today, we’re developing next generation solutions to meet the newest challenges, including concentrated solar, biomass and geothermal.

Power Industry

Rapid load variations, frequent stops and starts, and the highest temperatures, flows and pressures. Welcome to fluid motion and control in the power industry. These grueling applications are where Flowserve became a driving force in power generation. To appreciate our role, you needn’t look further than our pioneering work in nuclear power or the massive machines we’ve built for conventional steam plants. But that’s history. Today, we’re developing next generation solutions to meet the newest challenges, including concentrated solar, biomass and geothermal.

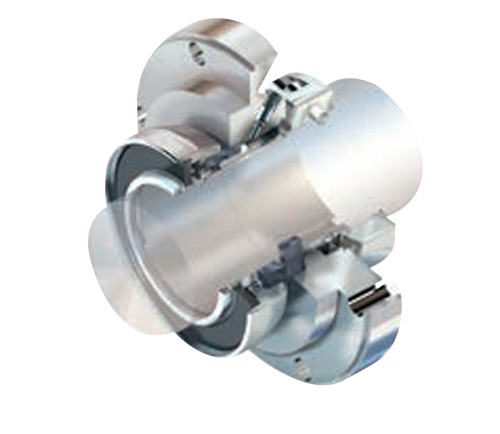

SLC seals are heavy-duty, single pusher cartridge seals built for the harshest slurry pump services found in mining, mineral and ore processing, and flue gas desulfurization. Suitable for solids to 60% by weight.

sPECIFICATIONS

Pressure: to: 20.6 bar (300 psi)

Temperature: -18°C to 110°C (10°F to 230°F)

Speeds to: 15 m/s (50 fps)

Shaft Sizes: 32 to 220 mm (1.250 to 8.661 in)

FEATURES & BENEFITS

- Lower operating costs ensured by unique non-clogging, encapsulated cone spring, which increases reliability and enables flushless operation

- Maximized equipment uptime provided by abrasion-resistant metal components and silicon carbide faces that extend seal life beyond that of slurry pump components

- Economical performance via clean, open design, which operates without flush water to reduce product dilution and eliminate flush water costs

- Ease of installation resulting from cartridge design that requires no special tools or bearing housing adjustments

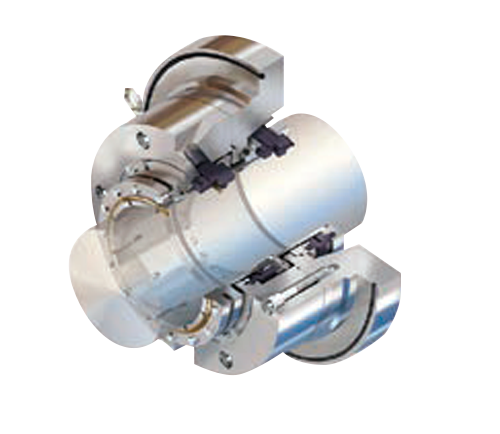

The balanced single cartridge pusher seals has a flexible stator and operates without outside flush liquid to eliminate product dilution, increase plant efficiency and reduce costs.

SPECIFICATIONS

Pressure: to: 17.2 bar (250 psi)

Temperature: -40°C to 149°C (-40°F to 300°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 50 to 235 mm (2.000 to 9.250 in)

FEATURES & BENEFITS

- Increased reliability and consistent “no visible leakage” operation due to line-on-line, hydraulically balanced faces

- Extended seal life enabled by centroid-loaded monoblock rotor that helps to maintain zero net deflection, reducing leakage and wear

- Reduced maintenance costs provided by large cross-section stator O-ring, which allows maximum shaft movement while reducing the damaging effects of hang-up

- Dependable performance provided by single seals handling solids to 20%, dual seals to 60% solids, and quench options providing complete application flexibility

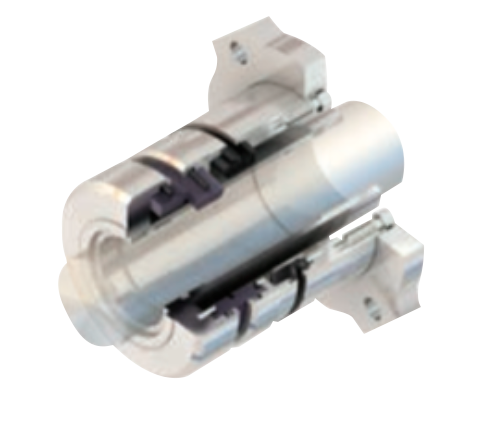

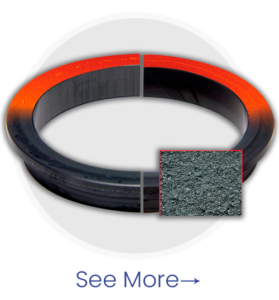

The RIS rubber-energized, component slurry seal features a unique non-clogging design that does not utilize springs or bellows. Handles solids to 50% by weight.

SPECIFICATIONS

Press. to: 10.3 bar (150 psi)

Temperature: -4°C to 110°C (25°F to 230°F)

Speeds to: 11 m/s (36 fps)

Shaft Sizes: 32 to 235 mm (1.250 to 9.250 in)

FEATURES & BENEFITS

- Ease of installation provided by innovative adaptive components that allow the seal to be installed from the wet end and adjusted externally

- Longer MTBF from non-clogging elastomer spring design that has no dynamic O-ring to hang up

- Reliable operation ensured by the rubber-energized stationary seal face that holds the seal faces together and absorbs relative shaft movement

- Reduced operating costs and improved control made possible by flushless operation, which is especially beneficial in flue gas desulphurization

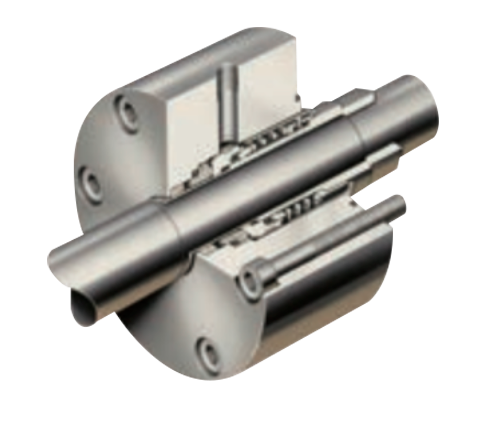

QB Series balanced pusher seals are ideal for medium-duty applications in power and industrial applications.

SPECIFICATIONS

Pressure: to: 51.7 bar (750 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 12.7 to 139.7 mm (0.500 to 5.500 in)

FEATURES & BENEFITS

- Greater reliability and installation ease assured by rugged components, heavy-duty seal faces and cartridge seal configuration

- Combat dirty services with the clog-resistant large cross-section, single coil spring in the QBS seal

- Handle low lubricity hot water without the need for auxiliary cooling systems with the QBU seal

- Choice of throttle bushing design: fixed, floating or segmented for safe equipment operation

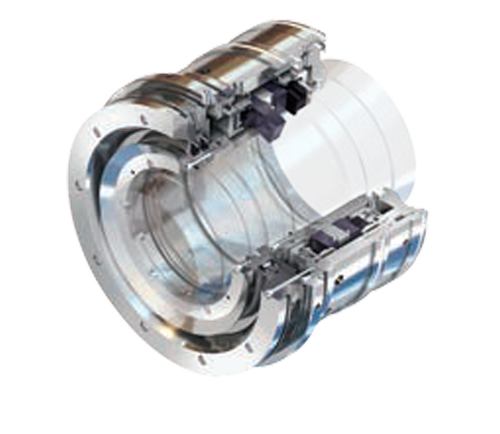

D Series single spring, balanced pusher seals have a high-circulation integral pumping ring to ensure proper cooling. Ideal for high-temperature boiler feed water and hot hydrocarbon services.

specifications

Pressure: to: 103.4 bar (1500 psi)

Temperature: -73°C to 343°C (-100°F to 650°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: 13.4 to 137 mm (0.525 to 5.400 in)

FEATURES & BENEFITS

- Cost-effective operation ensured by integrated pumping ring that eliminates the expense of cool injection systems

- Greater reliability due to the rotating face that remains flat under all conditions for very low leakage

- Consistent seal face contact provided by robust U-cup seal and spring holder

- Superior high-temperature performance enabled by large, low spring rate single coil spring that tolerates axial setting variations

The Series 80 seal is one of Flowserve’s Heritage products that has a proven track record of performance. Built with premium materials, this Stationary designed, Hydraulically balanced seal succeeds in the most challenging applications.

Flowserve spun off the more popular sizes of the Series 80 and formed the CPM seal which allows us to compete with today’s low cost seal manufactures. The CPM line of seals are used for competitor change outs in general service applications.Compaired to other light duty seals, the CPM seal weights 30% more due to the heavy duty gland design. The flush port is also larger than most light duty seals making the CPM seal a better all-around choice.

SPECIFICATIONS

Press. to vacuum to 400 psig (27 bar)

Temp: -40 to 400 F (-40 to 204 C)

Speeds to: 100 ft/min (30m/s)

Sizes: 3/4″ to 3.750″

FEATURES & BENEFITS

- Robust rotary face design is flexibly mounted, enhancing the ability to survive shock and face distortion typically found in clamped seal face designs.

- Springs located outside the process fluid deter chemical stress corrosion and spring clogging by dirty process fluids.

- Hydraulically balanced seal design reduces friction, heat and wear with lower loading forces while maintaining a lubrication film between the mating faces.

- Floating stationary to accommodate out-of-square pump misalignment.

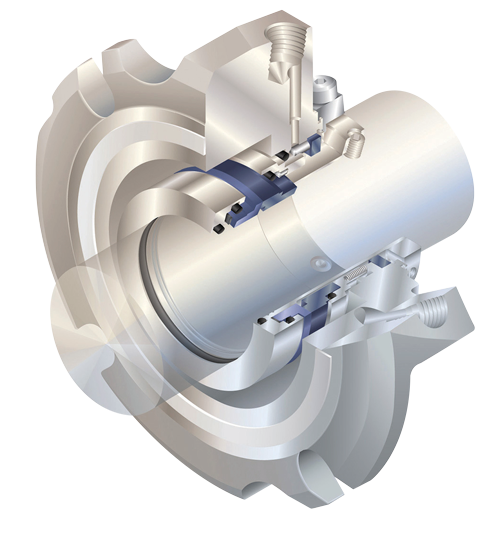

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

specifications

Pressure: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temperature: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Shaft Sizes: pusher 25 to 200 mm (1.000 to 8.000 in); bellows to 95 mm (3.750 in)

FEATURES & BENEFITS

- Lower total cost of ownership from advanced seal design features that enable superior reliability

- Broad application flexibility assured by comprehensive range of pre-engineered configurations and materials; custom solutions also available

- Reduced operating costs via standardization to ISC2 Series, which enables less inventory, greater flexibility, less downtime and longer seal life

- Increased plant and personnel safety delivered by cartridge security and compliance with all major international standards

These dual cartridge pusher seals from the versatile ISC2 Series bring superior reliability to ASME, ISO, JIS and API pumps used in chemical, power, water, oil and gas, and other industries.

specifications

Press. to: 20.6 bar (300 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

FEATURES & BENEFITS

- Reliable operation resulting from advanced volute groove design and internal circulating devices that promote cool running

- Longer service life via a stationary face support drive mechanism that reduces wear in applications with high vibration levels, and springs and pins outside the process for reduced corrosion and clogging

- Application flexibility with double-balanced seal face geometry, allowing both pressurized and unpressurized operation; ISC2-682PP provides full API 682 compliance

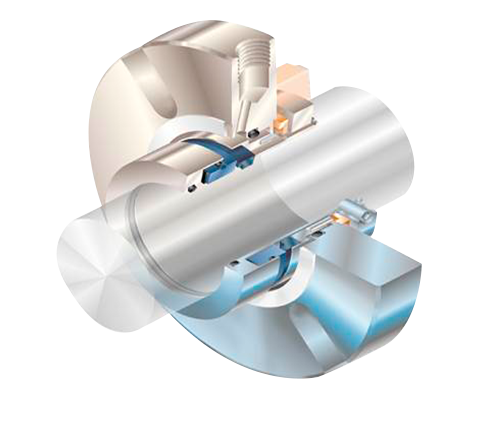

The Gaspac is a proven platform of dry gas seals for turbomachinery equipment and features either bi-directional T-Groove or Advanced Pattern Groove (APG) non-contacting seal face technologies.

SPECIFICATIONS

Pressure: to: 650 bar (9427 psi)

Temperature: to 230°C (450°F)

Speeds to: 250 m/s (820 fps)

Shaft Sizes: to 360 mm (14.125 in)

FEATURES & BENEFITS

- Environmental regulatory compliance and energy savings assured by controlled gas flow rates over the widest operating conditions

- Increased reliability with precision face topography that offers high film stiffness and damping, and maintains a stable gas film under slow roll and high speeds

- Application versatility from a wide range of single and dual configurations with process barrier and oil exclusion features

- Increased uptime via innovative solutions for secondary sealing, reverse rotation, reverse pressurization and component centering

- For more information on installation of this seal, please contact Carolina Seals, Inc.

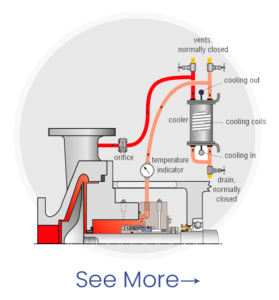

Water seal coolers lower the temperature of process/barrier fluid to improve seal reliability. Designed and manufactured in accordance with ASME Section VIII, Div 1 and PED.

specifications

Press: to 183 bar (2650 psi)

to 95°C (200°F)

FEATURES & BENEFITS

- Easy installation in limited spaces due to compact design with integral mounting bracket and convenient pipe porting

- Simplified maintenance with quick access to coil, only one bolt fastening the shell, and no disturbance to piping during shell removal

- High-temperature fittings included as standard

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements

DuraClear high-performance synthetic lubricants are specially formulated for dual mechanical seal barrier or buffer fluids to increase mean time between planned maintenance and reduce energy consumption.

specifications

NSF H-1 Food Grade

ISO 5, 7 and 32 viscosities available

FEATURES & BENEFITS

- Process fluid compatibility assured by synthetic oils and oil blends readily available with food grade compliance; DuraClear Crystal 7 is chemically inert and non-reactive for the most aggressive services

Extended seal life with reduced friction and wear, oxidation resistance, temperature stability and low volatility

- Increased drain and replenish intervals due to longer fluid life

Increased uptime with formulations for bearing frame oil, compressor oil, gear oil, hydraulic oil, turbine oil, air tool lubricant and grease applications