Pharmaceutical

Our products and services emphasize precision, purity, and safety, adhering to the needs of pharmaceutical customers.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

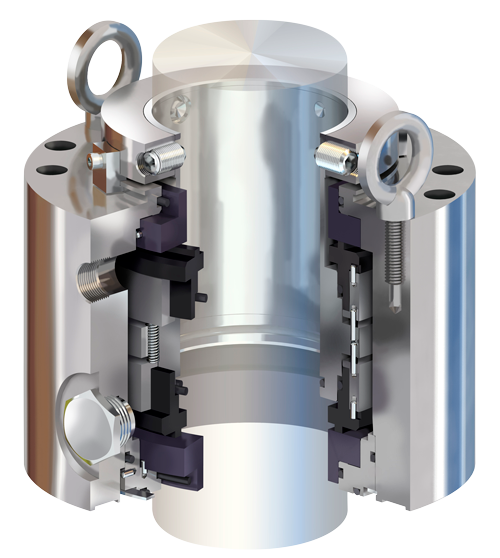

The VRA is an outside-mounted, dry-running single pusher seal designed to operate on top-entry agitators and mixers. Self-lubricating carbon or filled PTFE seal faces run completely dry without cooling.

Cost savings provided by contacting dry-running design and two-piece collar, which respectively eliminate the need for a buffer fluid system and expensive alloys in non-wetted areas

SPECIFICATIONS

Press: vacuum to 13.8 bar (200 psi)

Temp: to 121°C (250°F)

Speed: to 350 rpm

Sizes: 25 to 178 mm (1.000 to 7.000 in)

Refer to literature FSD167 at flowserve.com/library.

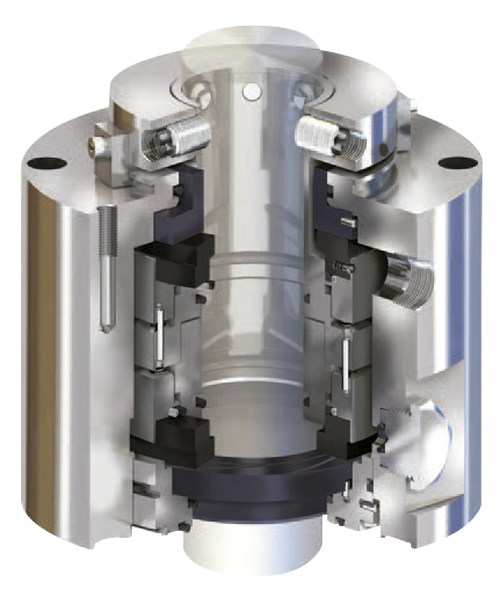

The Mixerpac family of mixer seals is designed for top-, side- and bottom-entry installations. Configurations available for slurry, sterile, high-pressure or large shaft movement applications.

Broad application flexibility owing to modular cartridge construction with and without bearing as well as liquid-lubricated and gas lift-off designs

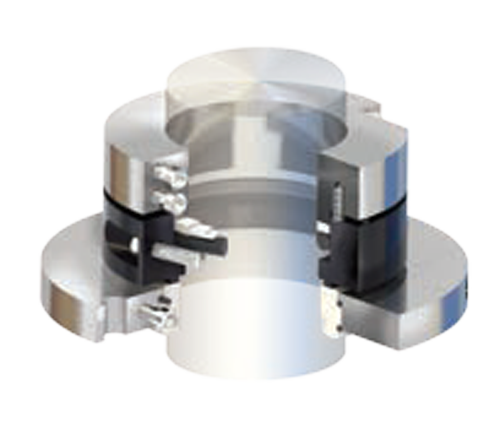

The MSS is for tough mixer and vessel applications where stuffing box face, bore and OD run-out are extreme. Typically used on older equipment or where compression packing had been used.

Easy installation, inspection and maintenance facilitated by outside seal arrangement and split design

SPECIFICATIONS

Press: vacuum to 7 bar (100 psi)

Temp: to 150°C (300°F)

Speed: to 1740 rpm

Sizes: 25 to 305 mm (1.000 to 12.000 in)

For more information, refer to FSD162.

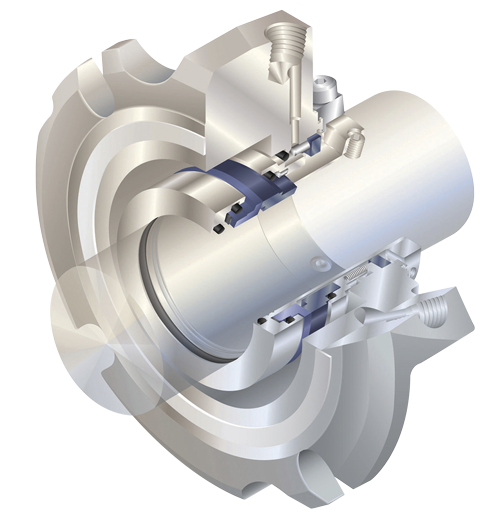

The ISC2 Series provides exceptional reliability and standardization over a wide variety of industrial applications and equipment. Available in single and dual arrangement, pusher and metal bellows types.

SPECIFICATIONS

Press: pusher to 20.6 bar (300 psi); bellows to 13.8 bar (200 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speeds to: 23 m/s (75 fps)

Sizes: pusher 25 to 200 mm (1.000 to 8.000 in);

bellows to 95 mm (3.750 in)

Refer to literature FSD243 at flowserve.com/library.

The ISC2-MW is a dual-arrangement standard cartridge pusher seal engineered for reliable, cost-effective operation in mixer service.

SPECIFICATIONS

Press: to 6.9 bar (100 psi)

Temp: -40°C to 204°C (-40°F to 400°F)

Speed: to 1.1 m/s (3.5 fps)

Sizes: 25 to 200 mm (1.000 to 8.000 in)

For more information, refer to FSD104.

I am text block. Click edit button to change this text. Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.