Base Plates/Guards

Base Plates/Guards

Since 1982 Summit Pump, Inc has manufactured quality pumps and pump parts for industry worldwide. The company mission statement is more than just a plaque on the wall; it is how we strategically go to market. We will “provide quality pumping products in a timely manner, at a fair market price”. Located in Green Bay, Wisconsin we are a privately held and financially strong company. We sell our products worldwide via a dedicated and exclusive distribution network. We pride ourselves in being the Best Value in the market.

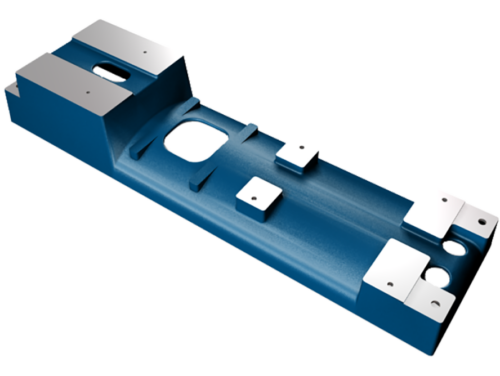

Polymer Concrete

FEATURES

- ANSI B73.1 M Dimensions

- Excellent Corrosion Resistance

- Vibration Dampening: Superior to Steel and Iron

- Integrally Molded Catch Basin

- 304 Stainless Steel Inserts

- Barrel type coupling guards will bolt directly to many common models of pumps including: Goulds®, Durco®, Summit™, Peerless® and others.

Optional Features

- Custom Sizes

- Custom Colors

- Hastelloy-C Inserts

- Leveling Screws

- Compatible Grout

- Integrally Molded Grout Holes

OEM brand names are for reference only and in no way indicate that Summit is affiliated with any of the above OEM’s or does it indicate that we are supplying OEM parts.

Goulds® is a registered trademark of ITT Manufacturing Enterprises, LLC

Durco® is a registered trademark of Flowserve Management Company

Peerless® is a registered trademark of Sterling Fluid Systems (USA) LLC

Brochures

Download

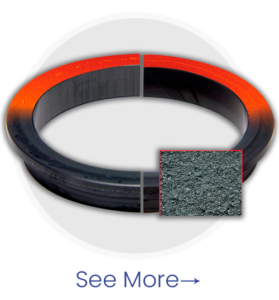

Guards

FEATURES

- Economically Priced

- Available in Safety Yellow or Safety Orange

Barrel type coupling guards will bolt directly to many common models of pumps including: Goulds®, Durco®, Summit™, Peerless® and others.

OEM brand names are for reference only and in no way indicate that Summit is affiliated with any of the above OEM’s or does it indicate that we are supplying OEM parts.

Goulds® is a registered trademark of ITT Manufacturing Enterprises, LLC

Durco® is a registered trademark of Flowserve Management Company

Peerless® is a registered trademark of Sterling Fluid Systems (USA) LLC

Brochures

Download

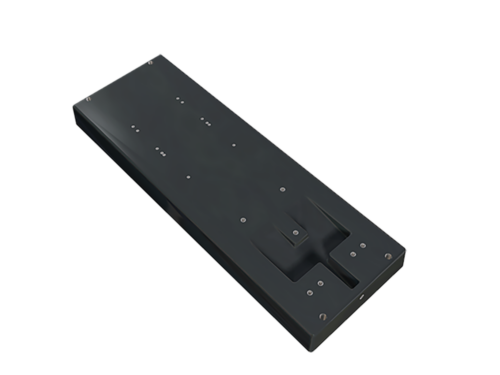

Cast Iron & Fabricated

Features

- ANSI B73.1 M dimensions

- Base Plates in stock

- Custom base plates, fabricated only

- Painted

Optional Features

- Multiple materials for fabricated base plates

- Drill and tap options

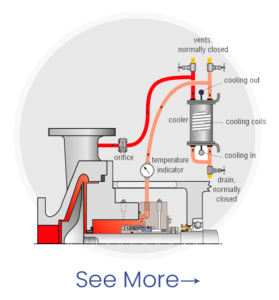

Flowserve reservoirs are available for dual pressurized (Plan 53A) and dual non-pressurized (Plan 52) mechanical seals. Options are available for utilizing water or oil as barrier fluid.

specifications

Press: to 82.3 bar (1200 psi)

Temp: to 148°C (300°F)

Volume: to 20 L (5 gal)

FEATURES & BENEFITS

- Extended seal life made possible by reliable supply of clean buffer/barrier fluid for cooling and lubrication

- Reduced maintenance and operating costs with optimal buffer/barrier fluid management

- Increased reservoir life with corrosion-resistant 304, 316 or 316L construction

- Compliance with API 682, ASME Section VIII, ASME B31.3, PED and/or TRD as required

- Application flexibility provided by configurations and instrumentation that are easily adapted to local standards as well as application and customer requirements

The Seal Gard manages seal water flow rates for single and dual seals to improve the mean time between planned maintenance of your rotary equipment by improving the environment in the seal area.

specifications

Flows to: 13 lpm (3.5 gpm)

Press. to: 25 bar (363 psi)

Temp: 0°C to 100°C (32°F to 212°F)

FEATURES & BENEFITS

- Lower operating cost from dependable flow control that saves water costs by reducing seal water usage

- Ease of operation assured by clear-view acrylic flow meter with vertical flow tube that resists fouling and vibration-resistant pressure gauge

- Reduced downtime enabled by standard check valve that prevents backup of product into the seal water line in the event of pressure reversal